Flavors are essential to the food and beverage industry, shaping consumer experiences globally. As demand rises for sustainable, clean-label, and natural flavor alternatives, the industry faces challenges such as resource scarcity, environmental concerns, and strict regulatory requirements.

Biotechnology provides a promising solution by enabling the production of natural, allergen-free, and vegan flavors that meet regulatory standards while reducing environmental impact. By leveraging advanced tools and techniques, biotechnological innovations address consumer expectations for healthier and more sustainable flavor options, ensuring both scalability and economic viability.

With the growing preference for clean-label and natural products, biotechnology is increasingly influencing the development of flavors. This discussion focuses on recent advancements, key challenges, and opportunities in biotechnological flavor production, offering a detailed perspective on the evolving industry landscape, consumer trends, and the adoption of FDA-approved natural ingredients.

Signicent provides in-depth patent landscape analysis to help clients understand emerging trends, competitive insights, and potential opportunities in biotechnological innovations for flavor production.

Why Natural Flavors Outshine Artificial Alternatives in Stability and Sustainability?

Natural products have gained popularity due to their superior stability and health benefits. Here’s why they stand out:

- Enhanced Molecular Structures: Natural flavors possess organic compounds that maintain stability under varying processing conditions.

- Consumer Trust: Natural products resonate better with consumers looking for clean-label food and beverage options.

- Sustainability: Biotechnological methods enable natural flavor production, reducing the environmental footprint compared to synthetic alternatives.

- Regulatory Acceptance: Natural flavors face fewer regulatory hurdles, making them more market ready.

- Health Benefits: Artificial flavors often come with health risks, while natural products align with wellness trends.

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

Top Challenges in Flavor Production

Despite the promise of biotechnological solutions, the flavor industry grapples with several challenges:

- Low Yield and Resource Wastage: Traditional extraction methods for natural flavors often resulted in low yields, leading to significant resource wastage and higher production costs.

- Regulatory Compliance: Meeting strict global regulatory standards for natural and safe flavors was challenging due to the limitations of conventional production methods.

- Consumer Demand for Clean-Label Products: Rising consumer demand for natural, allergen-free, and vegan flavors created immense pressure on manufacturers who relied on outdated techniques.

- Instability of Extracted Flavors: Naturally extracted flavors were prone to degradation during processing and storage, making it difficult to maintain consistent quality and stability.

- Environmental Impact: Conventional flavor production methods were resource-intensive, contributing to significant environmental degradation and unsustainable practices.

- Scalability Issues: Scaling up production to meet growing demand was difficult, as traditional methods were labor-intensive and inefficient.

- Synthetic vs. Natural Dilemma: While synthetic flavors offered a cost-effective alternative, they faced backlash due to consumer concerns over health and artificial ingredients, leaving industries struggling to meet the demand for natural flavors.

- Complex Market Segmentation: Catering to diverse regional flavor preferences and profiles added complexity to production strategies, often requiring costly and inefficient adjustments.

Signicent’s technology scouting services identify new and emerging technologies in biotechnology, helping clients stay ahead in flavor production and sustainability practices.

Groundbreaking Biotechnological Innovations Transforming Flavor Production

There are several biotechnological innovations addressing the critical challenges in flavor production. Below are some essential techniques for redefining sustainability and efficiency:

1. Fermentation-Based Flavor Production: Microorganisms like yeast and bacteria are engineered to produce natural flavor compounds, reducing reliance on traditional extraction methods.

Benefits:

- Solves low yield issues by enabling scalable and cost-effective production.

- Reduces environmental impact by cutting resource wastage.

Applications:

- Vanilla flavor for desserts and beverages.

- Fruity and umami profiles for processed foods.

2. Enzyme-Based Biocatalysis: Enzymes catalyze specific reactions to synthesize complex flavor molecules with precision and minimal waste.

Benefits:

- Addresses flavor stability concerns by producing consistent, high-quality compounds.

- Reduces by-products, ensuring eco-friendly processes.

Applications:

- Ester flavors for beverages like juices.

- Aromatic compounds for confectionery.

3. Metabolic Engineering: Genetic modification of microorganisms enhances their ability to biosynthesize desired flavor compounds efficiently.

Benefits:

- Tackles consumer demand for natural and vegan flavors by creating allergen-free solutions.

- Customizes flavors for specific regional preferences.

Applications:

- Tailored flavors for plant-based meat alternatives.

- Diverse profiles for international cuisines.

4. Natural Product Extraction with Biotech Enhancements: Advanced biotech tools improve extraction efficiency from natural sources like plants and fruits.

Benefits:

- Overcomes low yield and scalability hurdles by optimizing natural extraction processes.

- Ensures higher stability of extracted flavors during storage.

Applications:

- Citrus flavors for carbonated drinks.

- Berry and mint extracts for candies and oral care products.

5. Plant Cell Culture Technology: Plant cells are cultivated in controlled environments to produce flavor compounds sustainably without over-harvesting natural resources.

Benefits:

- Eliminates environmental impact caused by conventional farming.

- Ensures year-round availability of rare flavors.

Applications:

- Exotic flavors like saffron and cardamom.

- Herbal infusions for teas and wellness products.

6. Microbial Engineering: Microorganisms are modified to directly produce flavors by mimicking natural biosynthetic pathways.

Benefits:

- Resolves the synthetic vs. natural debate by offering scalable, natural solutions.

- Reduces dependency on synthetic flavor chemicals.

Applications:

- Natural umami for snacks.

- Dairy-free flavors for plant-based milk and cheese.

Benefits of Biotechnological Innovations

- Sustainability: Reduces the ecological footprint through resource efficiency and minimal environmental impact.

- Clean Label Products: Meets consumer demand for allergen-free, vegan, and natural flavors, enhancing product trust and market appeal.

- Cost Effectiveness: Scalable solutions lower production costs, making premium flavors accessible to a broader audience.

- Flavor Consistency: Maintains stable and high-quality flavors, ensuring a superior sensory experience for consumers.

- Global Adaptability: Addresses diverse flavor preferences while adhering to strict regulatory standards worldwide.

Our technology gap analysis identifies areas for improvement in clients’ biotechnological processes, enabling better alignment with industry trends and consumer demands for natural flavors.

Rising Global Demand for Vegan, Allergen-Free, and Natural Flavors

The global shift towards plant-based diets and allergen-free products has fueled demand for biotechnological solutions:

- Vegan Flavors: Biotechnology enables the creation of flavors without animal-derived ingredients, catering to the growing vegan population.

- Allergen-Free Flavors: Biotech ensures precision in flavor development, eliminating allergenic components and enhancing safety.

- Clean Labels: Consumers prefer products labeled as natural and free from artificial additives, driving innovation in this domain.

We assist clients with Freedom to Operate (FTO) searches, ensuring that their biotechnological innovations are legally clear, minimizing risks associated with IP conflicts.

FDA-Approved Biotechnological Solutions for Flavor Production

FDA-certified biotechnological flavors are crucial for market acceptance. Key products include:

- Natural Vanilla Extract: Produced through fermentation, this extract ensures authenticity and compliance, offering consistent, high-quality flavor profiles without synthetic additives.

- Citrus Oils: Extracted using enzyme-based methods, citrus oils deliver exceptional purity and stability, ensuring natural, clean-label products.

- Mint Flavors: Engineered for consistent taste and aroma, mint flavors are ideal for confectionery, beverages, and other food products.

- Berry Flavors: Enhanced with metabolic engineering, berry flavors provide superior taste and longer shelf life, maintaining freshness throughout production.

Signicent’s biological sequence search helps clients identify and analyze genetic sequences in flavor production, supporting the development of innovative and natural biotechnological solutions.

How Biotechnology Creates Unique and Sustainable Flavor Products

Biotechnological methods have enabled the creation of unique products tailored to client needs:

- Plant-Based Meats: Flavors mimicking plant-based alternatives like mushrooms and lentils, derived through metabolic engineering, enhance their taste profile.

- Functional Beverages: Enzyme-enhanced fruit flavors are used in health drinks, offering rich, natural flavors with added nutritional benefits.

- Dairy Alternatives: Rich, creamy flavors are developed for almond, oat, and soy-based dairy alternatives, enhancing taste and texture.

Through detailed Market Assessment and Valuation, Signicent provides insights into market size, future trends, and segmentation, empowering clients to make informed strategic decisions in the flavor industry.

Flavor Market Segmentation: Natural, Synthetic, Vegan, and Allergen-Free

The biotechnological flavor market can be segmented as follows:

- By Type: The market includes natural, synthetic, vegan, and allergen-free flavors. Natural and allergen-free flavors are growing rapidly due to increasing demand for healthy, clean-label products.

- By Application: Biotechnological flavors are in high demand across food, beverages, pharmaceuticals, and cosmetics, as these sectors require tailored, sustainable, and safe flavor solutions for their products.

- By Region: The flavor market is segmented into North America, Europe, Asia-Pacific, and the Rest of the World. North America and Europe lead, with Asia-Pacific showing significant growth potential.

- Growth Drivers: The market is driven by consumer preferences for clean-label products, increasing vegan populations, regulatory mandates, and the demand for sustainable, allergen-free flavor solutions in multiple sectors.

We conduct thorough Patent Invalidity Search to help clients assess the strength of existing patents, reducing the risk of infringement in the rapidly evolving biotechnology and flavor sectors.

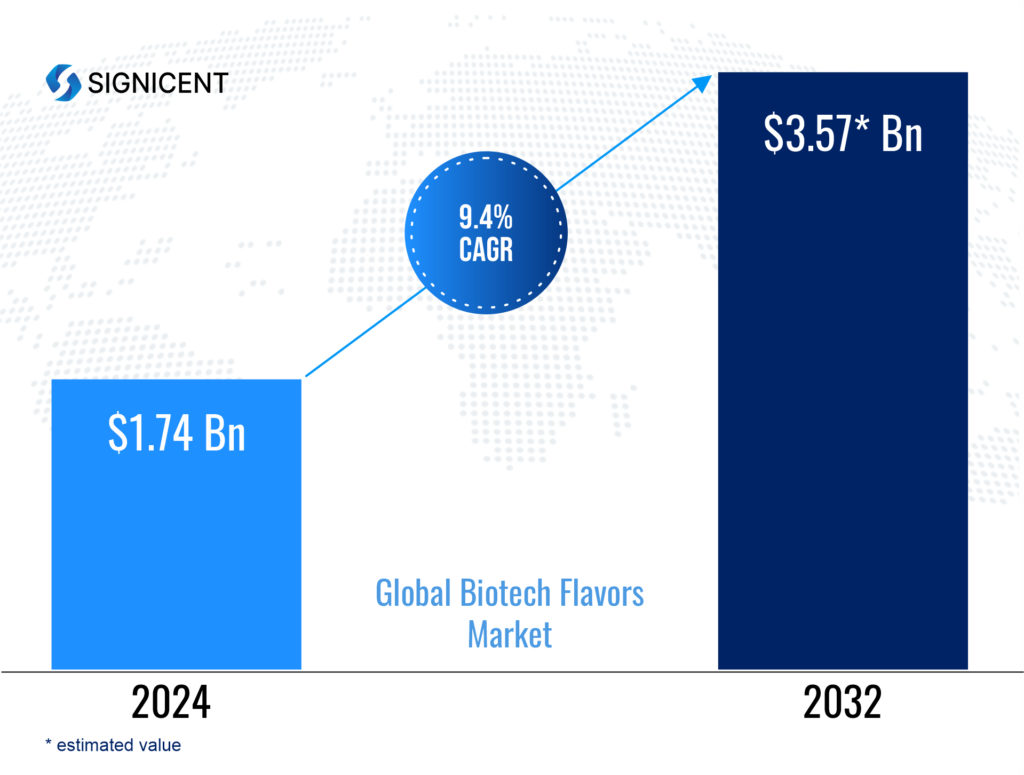

Market outlook:

As per Signicent’s Market Research, the Global Biotech Flavors Market size is likely to reach values in the ranges shown below.

Signicent’s competitive intelligence services offer insights into the competitive landscape, helping clients understand market leaders and their strategies in the biotechnological flavor industry.

Key players:

Here are the top 5 key players in the biotechnological flavor industry by revenue and region:

- Givaudan

- Firmenich

- International Flavors & Fragrances (IFF)

- Symrise AG

- Takasago International Corporation

Conclusion: The Future of Flavor Production

Biotechnology is transforming the flavor industry by addressing challenges and meeting consumer demands for natural, sustainable, and innovative products. With advancements in fermentation, enzyme-based biocatalysis, and metabolic engineering, the flavor market is poised for significant growth. Companies that embrace these technologies will not only cater to evolving consumer preferences but also gain a competitive edge in the global market.

By leveraging Signicent’s techno-market intelligence, businesses can stay ahead in this dynamic industry, ensuring their products meet regulatory standards and consumer expectations. The future of flavor production lies in biotechnology—a harmonious blend of innovation and sustainability.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Patent Landscape

- Patent Portfolio Analysis

- Patent Invalidity Search

- Patent Licensing Services

- Freedom to operate (FTO)

- Chemical Structure Search

- Design Patent Search

- Technology Scouting

- Technology Landscape Analysis

- Technology gap analysis

- Technology Intelligence

- Market Research

- Bio Sequence Search

- Manufacturers Search/ Supplier search

Elevate your Innovation and Research with Signicent’s cutting edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.