In today’s digital era, while technology continues to evolve rapidly, incidents of dangerous inflammable gas explosions and chemical container leaks are still claiming lives—day after day. From kitchen mishaps to highway horrors, explosions involving inflammable materials are claiming lives. Recently, a fatal traffic accident involving a truck carrying pressurised gas cylinders colliding with a passenger vehicle—an explosion ensued. Similar incidents have occurred in residential areas, where faulty or overheated gas containers caused devastating blasts. The root cause? Lack of early detection and absence of emergency safeguards is a problem.

But can technology rewrite this fate? Transportation of a broad range of inflammable materials—including gases (CNG, methane, sulfur dioxide), chemicals, coal, and other Inflammable substances—demands rigorous safety oversight. This blog explores how cutting-edge technologies are transforming the way we secure these volatile cargos.

AI and IoT are now offering life-saving potential by detecting gas leaks, monitoring temperature spikes, and triggering emergency protocols—before tragedy unfolds. At Signicent, our role in Market Assessment and Valuation empowers innovators to deploy the right solutions for inflammable material transport safety—across gases, chemicals, coal, and more.

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

Can AI Detect Problems Before They Occur?

AI is now the first line of defence since it can sense things that the human eye can’t see and respond faster than any human can. Here’s how AI-based systems offer real-world value:

- Detect micro leaks early: AI-integrated sensors continuously scan for small leakages invisible to human inspection in gas or chemical tanks.

- Overheat prediction in engines: ML models analyze engine data and predict chances of thermal runaway, especially critical when transporting coal or volatile chemicals.

- Valve failure alerts: AI can flag mechanical failures in valves or cylinder seals before pressure loss in gas transport units.

- Route risk prediction: AI tools assess route hazards in real-time—especially useful when transporting inflammable substances across rural or congested highways.

- Smart shutoff activation: AI can automatically cut the supply or stop a vehicle if conditions turn critical across any Inflammable cargo type.

Can Smart Tech Outperform Manual Safety Checks?

From fire-prone gas trucks to chemical leaks, discover how intelligent systems detect danger faster—and smarter—than manual monitoring ever could. Traditional methods often detect issues after disaster strikes. Let’s Compare

Manual vs. AI+IoT – A Comparative Look

| Aspect | Manual Monitoring | AI + IoT Optimization |

| Leak Detection | Visual/smell cues, often delayed | Real-time, precise sensor detection |

| Heat Monitoring | Manual checks, high error risk | Automated thermal sensors with live alerts |

| Response Time | Depends on driver awareness | Instant, automated responses |

| Maintenance | Periodic, guess-based | Predictive, data-driven scheduling |

| Safety Outcome | Reactive, often too late | Proactive, prevents escalation |

AI + IoT ensure early action whether the cargo is CNG, ammonia, sulfur dioxide, coal, or industrial solvents —spotting leaks, temperature surges, or pressure spikes in real time, long before human senses ever could. Because when lives and environments are at stake, milliseconds matter more than minutes.

The Role of IoT in Inflammable Container Safety

IoT is the digital nervous system of modern logistics safety, particularly for Inflammable materials:

- Integrated Leak Sensors: Detect leaks at molecular level across gas, chemical, or fuel containers—sensitive enough to pick up methane, but stable in coal dust environments.

- Overheat Monitoring Modules: Installed near engines or container valves (especially in coal and LPG carriers) to predict and prevent thermal ignition.

- Smart Brake Systems & Auto Shutoffs: Crucial for transporting explosives or chemical liquids, these systems automate response and reduce human error.

- Data Logging & Compliance: Especially valuable for regulated materials like industrial acids or petroleum derivatives.

- Real-Time Location & Condition Sync: GPS, humidity, and temperature sensors offer condition-aware visibility into every unit—gas tankers, chemical drums, or bulk coal trucks.

From Highways to Warehouses: Why Explosions Still Happen

Behind every explosion is a story of what could’ve been prevented. Poor maintenance, aging cylinders, unchecked leaks, and a lack of real-time alerts continue to turn transport routes and storage depots into high-risk zones. Without smart intervention, every journey carrying inflammable cargo carries the risk of becoming a tragedy.

- Inadequate training for drivers: Often seen in chemical and coal logistics, where emergency SOPs aren’t standardized.

- Aging infrastructure and containers: Leaky sulfur dioxide or rusty solvent drums are frequently found in underregulated markets.

- Overheating engines on long hauls: Especially in coal-dust-heavy zones or chemical-intensive transport routes.

- No real-time oversight from control rooms: A huge gap when flammable solvents or CNG are in transit.

- Loose safety regulations in developing countries: Weak enforcement around Inflammable goods standards prolongs outdated practices.

- Limited emergency response readiness: Local responders lack chemical fire training or tools for hydrocarbon or chlorine spills.

New-Age Innovations Solving Present-Day Dangerous Tragedies

These technologies are more than just upgrades—they’re lifelines. From corrosive leaks to ignition hazards, smart innovations are quietly rewriting safety standards and saving lives before tragedies make headlines. Explore the breakthroughs shaping a safer future below.

- Self-sealing gas valves: Prevent leak escalation in cylinders transporting butane, propane, or even corrosive industrial chemicals.

- Thermochromic warning labels: Used on solvent drums, coal containers, and fuel tanks to indicate danger zones visually.

- AI-powered dash cams: Prevent human errors like distracted driving in Inflammable materials fleets.

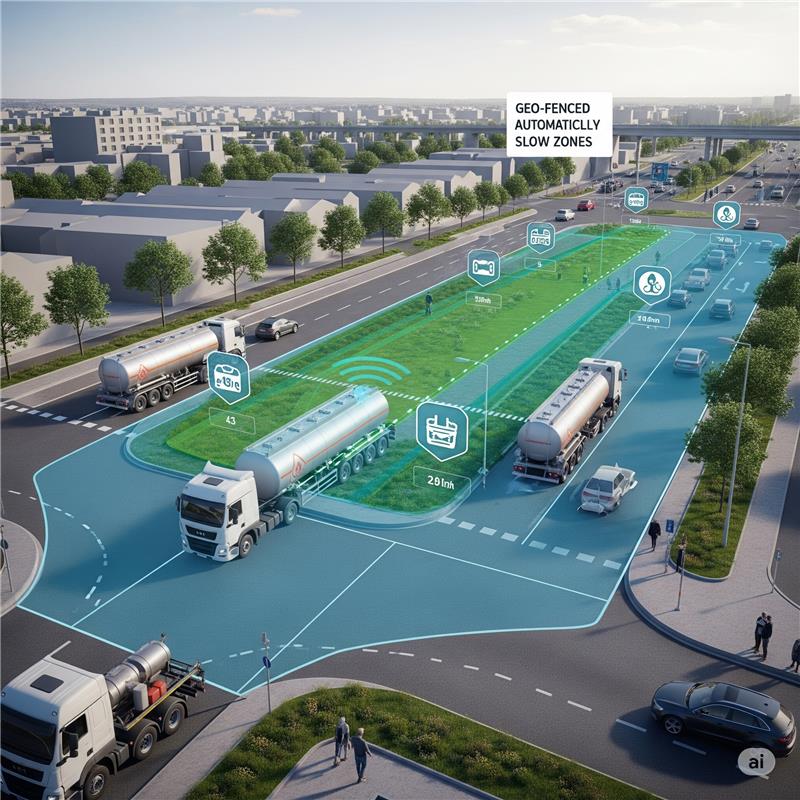

- Geo-fenced slow zones: Automatically slow vehicles carrying dangerous goods in high-risk areas.

- Smart packaging materials: Nano-coatings for drums or tankers resist corrosion from chemical acids or water in coal shipments.

- Mobile-based live tracking platforms: Used by handlers of both toxic gases and combustible solids for full traceability.

How Industry Leaders Are Transforming Inflammable Material Safety

Global giants are not only innovating but reshaping how gas, chemical, and coal logistics are secured in real time. Here’s how top companies are making that shift:

Honeywell — Smart Leak Detection & Emergency Shutdown Systems

Honeywell’s Gas Detection IoT Suite is being integrated across transport fleets and chemical warehouses. With real-time telemetry and auto-shutdown triggers, their system detects volatile leaks before human senses can — significantly lowering the risk of ignition and mass damage.

▶ Used in: Ammonia and propane logistics across North America and Southeast Asia.

3M — Thermochromic Labels for Hazardous Containers

3M has introduced temperature-sensitive labels that visually alert teams when solvents, coal drums, or gas tanks exceed safe thresholds. These labels turn bright red above 50°C, helping handlers act fast before a thermal event.

▶ Applied in: Global shipping operations for chemical plants and fuel stations in heat-prone regions.

Bosch — AI Dash Cams with Driver Behavior Analytics

Bosch has launched AI-enabled cabin monitors for hazardous material trucks that detect drowsiness, distraction, and even smoking. Alerts are sent to control centers in real-time, allowing for route rerouting or override.

▶ Deployed in: European fleets transporting sulfur dioxide, butane, and industrial chemicals.

Emerson — Smart Valves for Automatic Containment

Emerson’s self-sealing valve tech can detect pressure anomalies and instantly close gas flow from within. This innovation is particularly useful during CNG or chlorine cylinder transport, where micro-leaks can be deadly.

▶ Implemented by: Oil and gas contractors in the Middle East and emergency response vehicles.

Crucial Benefits of Using IoT & AI in the Digital Era

In today’s high-risk environment, smart systems are more than just technology; they save lives. From gas to chemicals, AI and IoT provide safety, speed, and control where it counts the most.

Below are the core benefits of embracing these next-gen innovations for hazardous material transport:

- Proactive Emergency Management: Smart triggers avoid flare-ups from petroleum, ammonium nitrate, or coal dust ignition.

- Reduced Human Dependency: Lowers risks in long-haul chemical routes and gas refill chains.

- Operational Efficiency: Less breakdown, more uptime—critical for time-sensitive cargo.

- Environmental Protection: Prevents spills of Inflammable chemicals or widespread methane leaks.

- Data-Driven Decisions: Identify recurring issues with specific materials—like CNG tanks or sulfuric acid drums.

Market Outlook

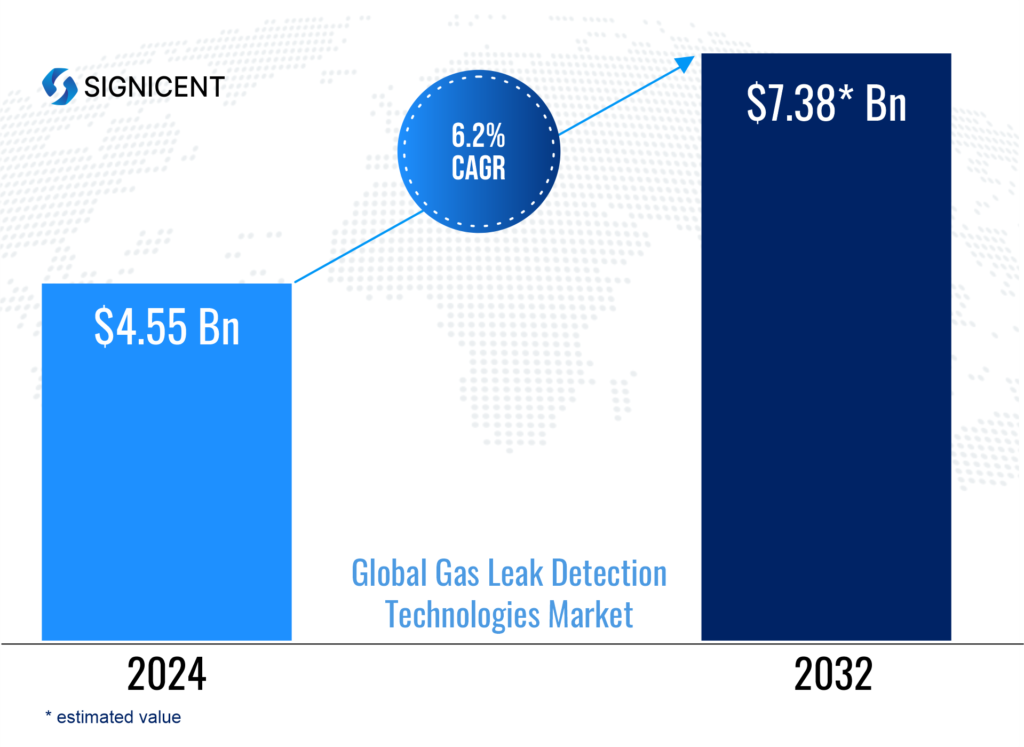

AI and IoT-based safety systems are gaining momentum as explosions and chemical leaks raise global concern. Industries like petrochemicals, mining, and logistics are adopting smart sensors, geo-fencing, and predictive tools to improve safety, reduce risk, and meet stricter transport regulations.

According to Signicent Market Research, the global gas leak detection technology market is accelerating—fueled by the rise of AI-integrated sensors, IoT-enabled alerts, and real-time diagnostics. The shift toward contactless detection, wearable gas monitors, and predictive analytics is also aligning with evolving safety regulations and sustainability goals across chemical transport and industrial sectors.

Key Players Driving Safety Forward

Below are the key players actively shaping the future of gas leak detection and inflammable cargo safety through real-time monitoring, smart logistics, and industrial-grade innovations.

- Bosch Mobility

- Linde PLC

- Honeywell

- Maersk Logistics

- FedEx

- XPO Logistics

- ABB

- Siemens

- Schneider Electric

- Emerson Electric

Signicent supports industrial safety pioneers by providing deep-dive technology landscape analysis for next-generation gas leak detection systems, AI-integrated safety modules, and IoT-enabled hazard monitoring platforms, transforming risk-prone logistics into intelligent, secure ecosystems.

Our Patent Landscape & White Space Analysis identifies innovation gaps in sectors such as self-sealing valves, edge-AI thermal sensors, chemical spill response technology, and predictive maintenance dashboards, enabling organizations to develop exclusive, future-proof safety solutions.

Whether you’re working on safer chemical transport, reducing gas leak incidents, or digitizing emergency protocols, Signicent delivers insights that move innovation from lab to logistics—safely and smartly.

Conclusion

In today’s volatile logistics environment, transporting inflammable materials is no longer just a matter of caution—it demands innovation. Traditional safety protocols are struggling to keep pace with the rising complexity of chemical cargo, CNG, and industrial gas logistics. From outdated containers to delayed emergency responses, the risks are real and recurring.

But with the rise of AI-powered detection, IoT tracking, smart packaging, and predictive systems, industries now have the tools to prevent disasters before they unfold. These technologies aren’t just safeguards—they are enablers of safer, smarter operations.

At Signicent, we believe that tackling high-risk challenges starts with actionable intelligence. Our role spans far beyond observation—we provide technology scouting, patent landscaping, and regulatory foresight to help businesses adopt cutting-edge safety solutions with confidence.

FAQs

Q1. What materials are commonly transported and considered highly inflammable?

A: Gases like CNG, methane, sulfur dioxide, propane, plus solids like coal, and various industrial chemicals.

Q2. What typically causes these transport disasters?

A: Leaks, engine overheating, poor container quality, route hazards, and collisions.

Q3. Can AI and IoT handle all types of Inflammable cargo?

A: Yes. These systems are designed to monitor, predict, and mitigate risks across gas, liquid, and solid combustibles.

Q4. Which companies lead in safe transport technology?

A: Bosch, Linde, XPO, Honeywell, Maersk, and FedEx among others.

Q5. What does Signicent do in this ecosystem?

A: We offer deep-tech scouting, IP landscaping, and innovation strategy to help stakeholders develop safer systems for Inflammable cargo movement.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Patent Landscape

- Patent Portfolio Analysis

- Patent Invalidity Search

- Patent Licensing Services

- Freedom to operate (FTO)

- Chemical Structure Search

- Design Patent Search

- Technology Scouting

- Technology Landscape Analysis

- Technology gap analysis

- Technology Intelligence

- Market Research

- Bio Sequence Search

Elevate your Innovation and Research with Signicent’s cutting-edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.