Introduction: The Hidden Cost of Material Waste

Every year, millions of tons of products—ranging from consumer electronics to medical devices and packaging—are discarded due to material degradation, cracks, and functional failures. The environmental impact is devastating, overflowing landfills, polluting oceans, and ecosystems disrupted by non-biodegradable waste.

But what if materials could heal themselves? Imagine a smartphone that repairs its own scratches, a medical implant that mends internal wear, or packaging that reseals after damage. Self-healing materials are no longer science fiction—they are a reality, offering a groundbreaking solution to sustainability challenges.

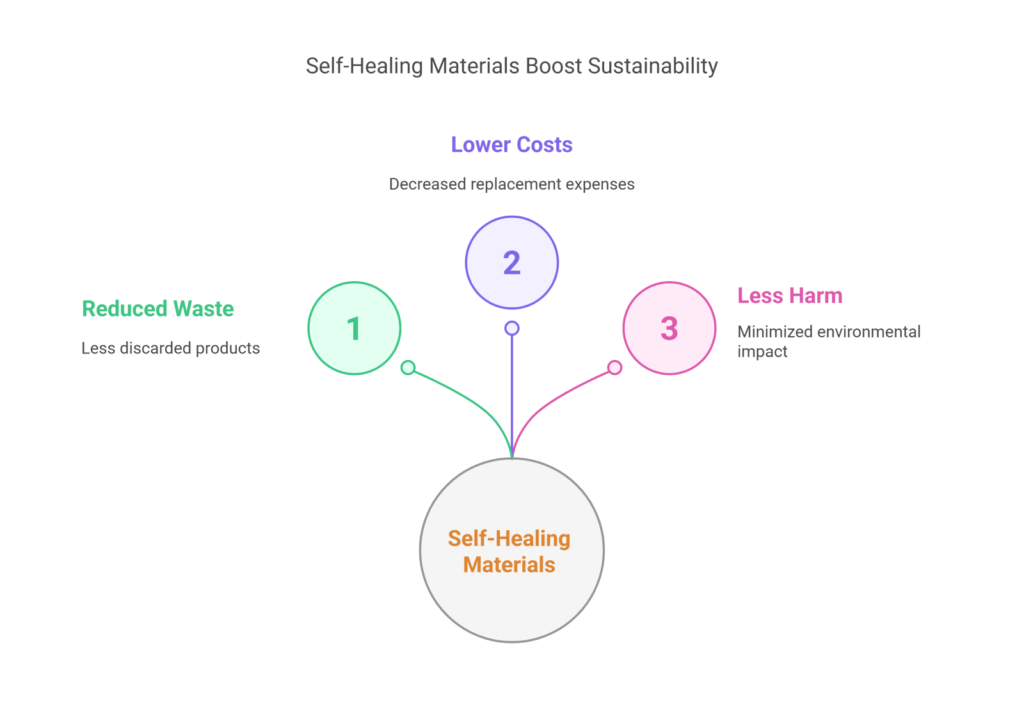

Industries are under increasing pressure to reduce waste and adopt circular economy models. Self-healing materials present a transformative opportunity to extend product lifespans, reduce replacement costs, and minimize environmental harm.

Can self-healing technology solve the critical problem of discarded products? This blog explores how these materials work, their real-world applications, challenges, and future potential. Our technology scouting services uncovered several emerging startups focusing on bio-based healing agents, which were further analyzed through freedom to operate (FTO) search services to mitigate litigation risks.

A million discarded items yearly… Is this sustainable?

Can self-healing materials solve these crucial challenges for consumers and industries alike?

Globally, over 50 million tons of electronic waste (e-waste) are generated yearly, with millions more from medical, automotive, and packaging industries. Most of these discarded products suffer from minor damages—cracked screens, worn-out coatings, or structural weaknesses—that render them unusable.

Self-healing materials, embedded with microcapsules, shape-memory polymers, or bio-inspired mechanisms, can autonomously repair damage. This technology:

- Reduces replacement costs for consumers

- Cuts industrial waste by extending product lifecycles

- Lowers carbon footprint by decreasing manufacturing demand

For instance, a self-healing smartphone screen could prevent millions of devices from being discarded annually. Similarly, self-repairing medical implants could reduce risky replacement surgeries.

How They Combat Product Waste

Their core value lies in tackling the very reason so many products are discarded: damage and degradation.

- Extended Lifespan: By repairing minor damages before they escalate, these materials drastically increase the operational life of products.

- Reduced Replacements: Fewer failures mean fewer products need to be thrown away and replaced, directly cutting down on waste generation.

- Enhanced Durability: Products become more robust and resilient to everyday wear and tear, maintaining their value and function for longer.

But how exactly do these materials work, and where are they making the biggest impact?

So, what exactly are these “miracle” materials? In simple terms, self-healing materials are synthetic or semi-synthetic substances engineered with the intrinsic ability to autonomously repair damage over time, often without external intervention.

Think of it like the human skin healing a cut – these materials can sense failure (like cracks or scratches) and initiate a chemical or physical process to restore their original integrity and functionality. To explore the evolution of autonomous healing systems, we began with an in-depth patent landscape analysis that revealed recent breakthroughs in microencapsulation and polymer chemistry.

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

How Self-Healing Materials Work & Their Key Benefits

While the field is diverse, self-healing materials commonly rely on various mechanisms to repair damage and restore functionality.

- Microencapsulation

- Tiny capsules filled with healing agents (e.g., polymers, resins) are embedded in the material.

- When cracks form, the capsules rupture, releasing the healing agent to fill gaps.

- Reversible Polymers

- Certain polymers can reform molecular bonds when exposed to heat, light, or moisture.

- Example: Diels-Alder polymers used in automotive coatings.

- Vascular Systems: Tiny, interconnected channels (like blood vessels) within the material circulate healing agents, delivering them to damaged sites when needed.

- Intrinsic Healing: The material’s own chemical structure is designed to reverse damage. This often involves reversible bonds that can break and reform, triggered by stimuli like heat, light, or rest.

Industries Benefiting from Self-Healing Tech:

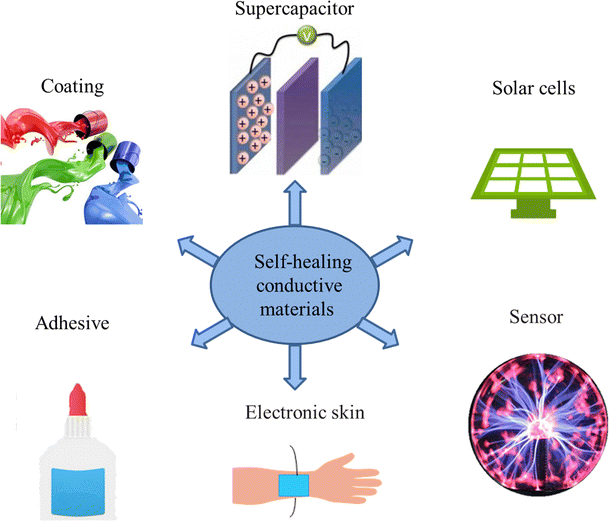

Industries benefiting from self-healing tech are rapidly expanding, with key applications including:

- Electronics: Flexible circuits and wearable devices that self-repair after stress or damage.

- Medical Devices: Implants and prosthetics that maintain integrity over time.

- Construction: Concrete that seals cracks autonomously, enhancing structural longevity.

- Packaging: Materials that reseal after punctures, preserving product freshness.

- Automotive: Coatings that heal scratches, maintaining vehicle aesthetics.

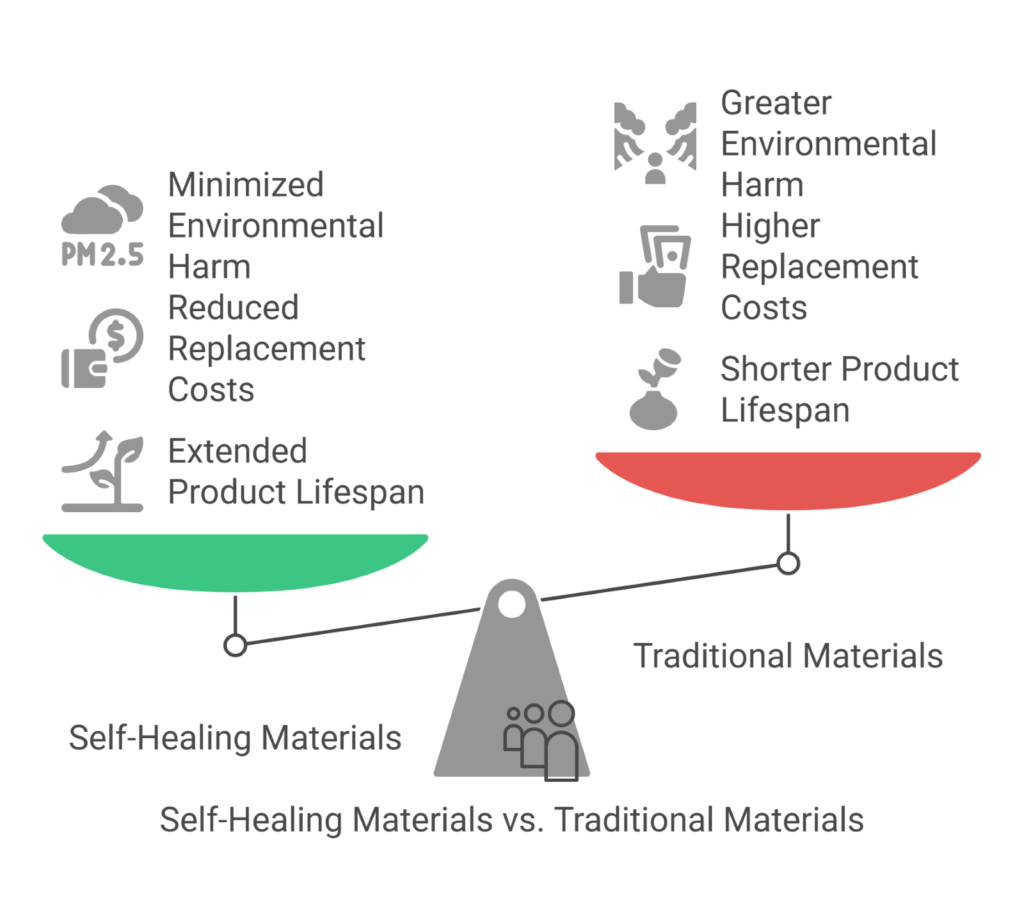

Challenges in Current Materials & Environmental Impact

Our materials simply cannot keep up even with better technology; they break, accumulate as waste, drain our wallets, and subtly harm the earth daily. These are some important issues resulting from material fragility and the consequent waste:

1. Short Product Lifespans: Minor damage like cracked screens or scratched surfaces often leads to early disposal, fueling unnecessary consumerism and crowding our landfills faster than we can manage.

2. Financial Drain: From personal gadgets to industrial machinery, replacements come at a steep price—draining budgets, increasing downtime, and stressing both households and businesses alike.

3. Plastic Pollution Crisis: Single-use plastics and non-biodegradable materials continue to choke marine life and ecosystems, pushing our environment further into a state of irreversible harm.

4. Energy-Intensive Manufacturing: Constant production of new materials consumes immense energy, directly contributing to higher emissions and clashing with our global push for carbon neutrality.

5. Medical Device Failures: Worn-out implants or malfunctioning prosthetics mean risky surgeries and additional recovery time, creating emotional, physical, and financial burdens on patients and healthcare systems.

6. Electronic Waste (E-Waste): Poorly built devices lead to more than 53 million tons of toxic e-waste each year—most of which remains unrecycled, polluting land and water.

7. Packaging Waste: Easily torn, punctured, or discarded packaging floods landfills, especially plastics that can take centuries to decompose, worsening the already dire waste crisis.

New Age Solutions: The Beginning of Personal Repair

The limitations of traditional materials are paving the way for innovation. Self-healing materials represent a paradigm shift, moving from passive components to active systems capable of self-preservation.

Microvascular Networks: Inspired by the human circulatory system, these networks release healing agents when cracks appear. This innovation is already in use across the aerospace sector, especially for preventing fatigue-induced cracks in aircraft components.

Benefit: Extends material lifespan and cuts down the frequency of manual repairs.

Shape-Memory Alloys: These advanced materials have the unique ability to return to their original shape when exposed to heat. They’re currently making waves in the medical field, especially in stents and robotic surgical tools where flexibility and precision are critical.

Benefit: Offers smart recovery in high-stress environments with minimal external input.

Bio-Inspired Polymers: By mimicking the self-repair abilities found in biological systems like human skin, these polymers are transforming the design of soft robotics and next-gen wearable devices.

Benefit: Enables energy-efficient, eco-conscious healing in materials exposed to repetitive stress.

3D-Printed Self-Healing Structures: Through advanced additive manufacturing, materials are printed with built-in self-repair capabilities. Automotive interiors and lightweight building components are early adopters of this innovation.

Benefit: Reduces the need for replacements while enhancing design flexibility and cost control.

AI-Integrated Healing Systems: This approach combines material science with smart algorithms. Sensors detect damage and automatically trigger localized repair processes, already being explored in textiles, electronics, and infrastructure.

Benefit: Offers predictive maintenance and prolongs product life through real-time adaptive healing.

Nanotech-Enhanced Coatings: Nanoparticles are used to form ultra-thin, invisible layers that repair minor scratches and abrasions. Electronics manufacturers and solar panel producers are integrating this to improve surface durability.

Benefit: Preserves product aesthetics and functionality with minimal human intervention.

For clients working on antimicrobial coatings and smart packaging, we conducted a detailed chemical structure search to identify patentable novel materials.

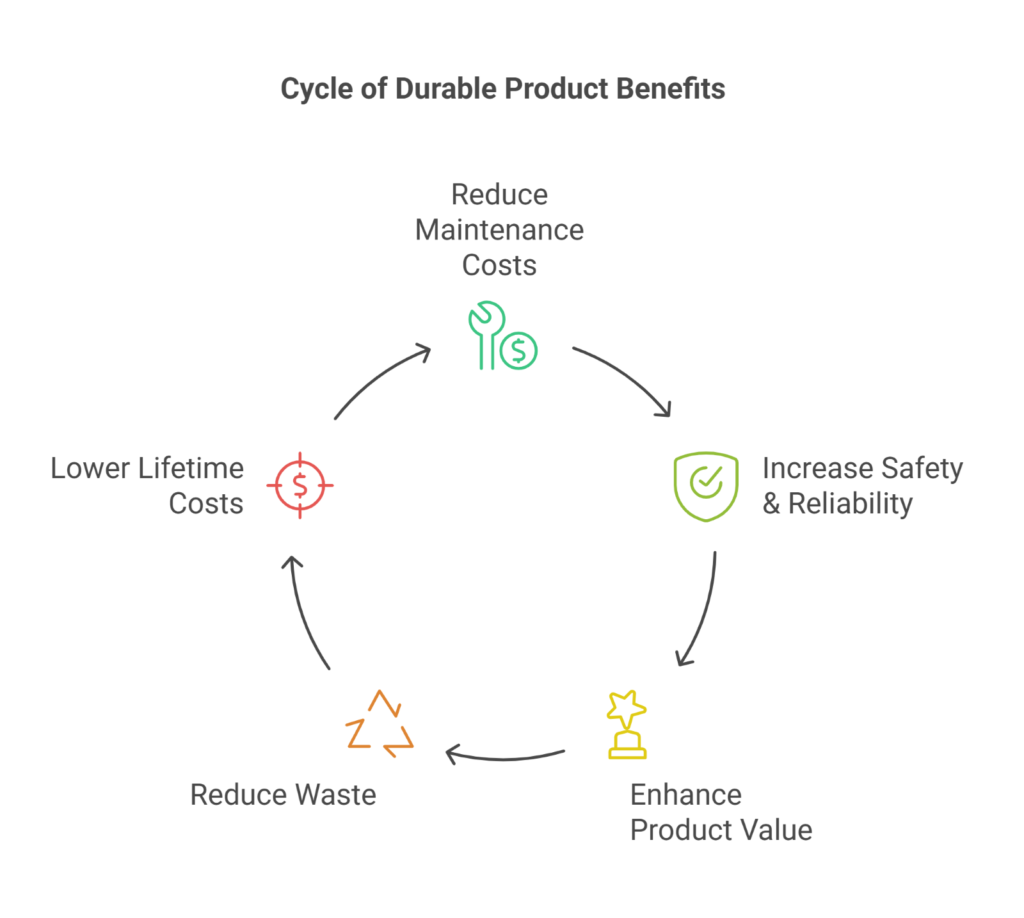

Tangible Advantages in Practice

It’s about what they truly offer in the real world, not only about smart materials. These developments fix costs, reduce waste, and slowly create a better system behind the scenes. Here’s how they’re making a measurable difference:

- Reduced Maintenance Costs: Less need for manual inspection and repair, especially in hard-to-reach or critical applications (e.g., wind turbines, pipelines).

- Increased Safety & Reliability: Minimizing the risk of catastrophic failure due to undetected micro-damage in structural components or devices.

- Enhanced Product Value & User Experience: Products that last longer and maintain their aesthetic appeal offer greater value and satisfaction.

- Significant Waste Reduction: Directly addresses the root cause of much product disposal, supporting circular economy goals.

- Lower Lifetime Costs: While initial costs might be higher, the extended lifespan and reduced maintenance often lead to lower overall ownership costs.

Real-Time Applications and Case Studies

Electronics:

Researchers have developed a stretchable, self-healing battery capable of retaining 90% capacity even after significant damage. This innovation holds promise for wearable technology and flexible electronics.

Construction:

In the UK, a self-healing road surface using recycled materials has been introduced, potentially extending road lifespans by 30% and reducing maintenance costs.

Medical Devices:

Self-healing hydrogels are being explored for use in wound dressings and implants, offering improved patient outcomes and reduced need for replacements.

We performed design patent search and biological sequence search to support innovation in self-healing hydrogels, especially for wearable medical applications.

Case Studies in Action (Illustrative Examples)

- Automotive Coatings: Companies are developing self-healing clear coats for cars. Minor scratches from car washes or road debris can disappear when exposed to sunlight (heat), maintaining the vehicle’s appearance and resale value longer.

- Aerospace Composites: Research focuses on self-healing composites for aircraft structures. Micro-cracks caused by stress or impacts could be autonomously repaired, enhancing safety and reducing costly, time-consuming inspections and repairs.

- Electronic Devices: Flexible electronics with self-healing conductive layers are being explored. This could lead to foldable phones or wearable tech that can repair minor circuit breaks caused by bending or stretching.

- Construction Materials: Self-healing concrete, often using bacteria or embedded capsules, can seal cracks caused by shrinkage or stress, extending the life of bridges, buildings, and infrastructure while reducing repair needs.

- Medical Implants: Coatings for implants that can self-repair minor surface damage could reduce friction, prevent infection footholds, and potentially increase the implant’s longevity within the body.

With our comprehensive approach that combines patent landscape search and technology scouting, we help bridge innovation with actionable business models.

Market Outlook: Growth and Key Players

The self-healing materials market is poised for significant growth, fueled by rising demand for durable, eco-friendly products and rapid advancements in smart polymers, coatings, and composites across automotive, electronics, aerospace, and construction sectors.

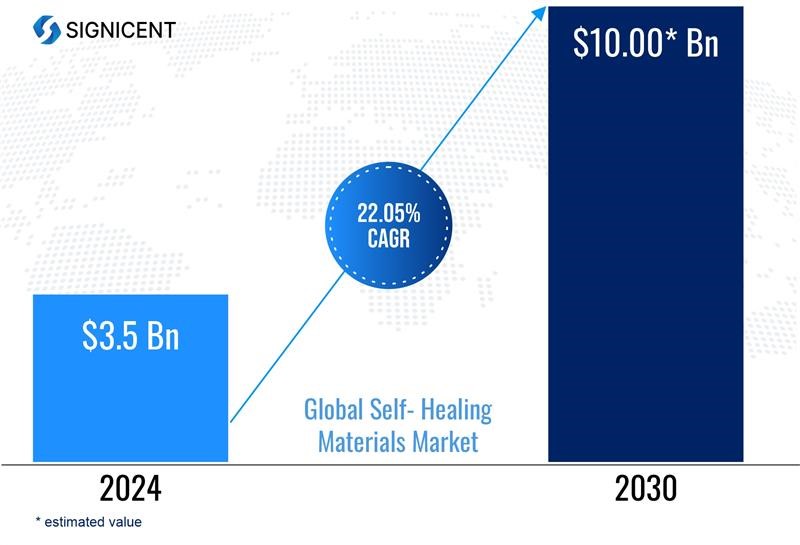

The global self-healing materials market is undergoing rapid transformation. As per Signicent Market Research, it is projected to reach the ranges below, driven by innovations in smart polymers, sustainable construction, and adaptive automotive components.

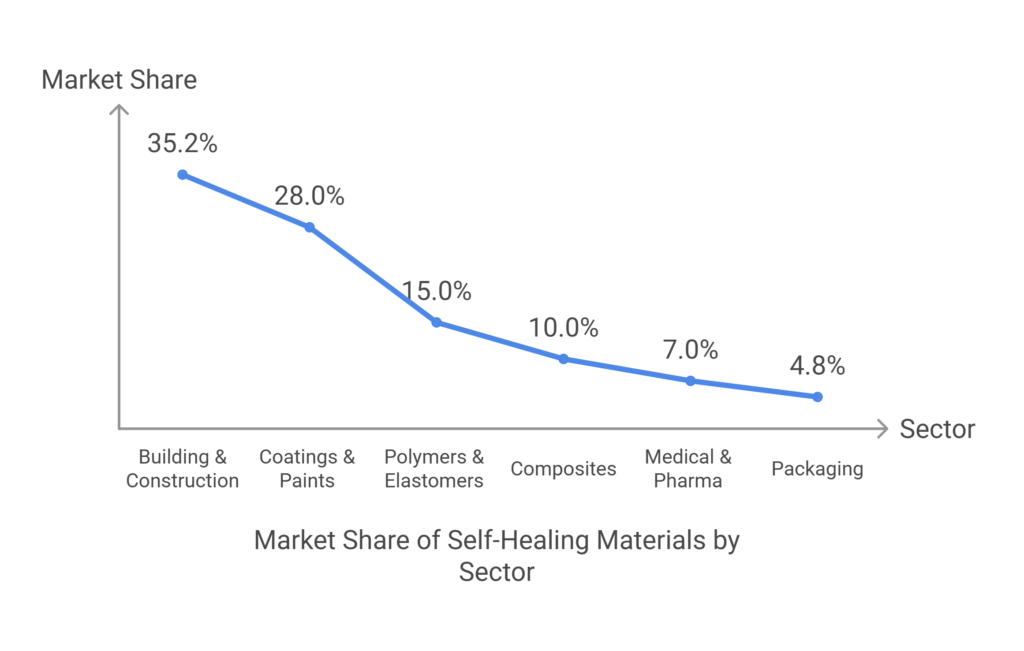

Market Analysis by Sector

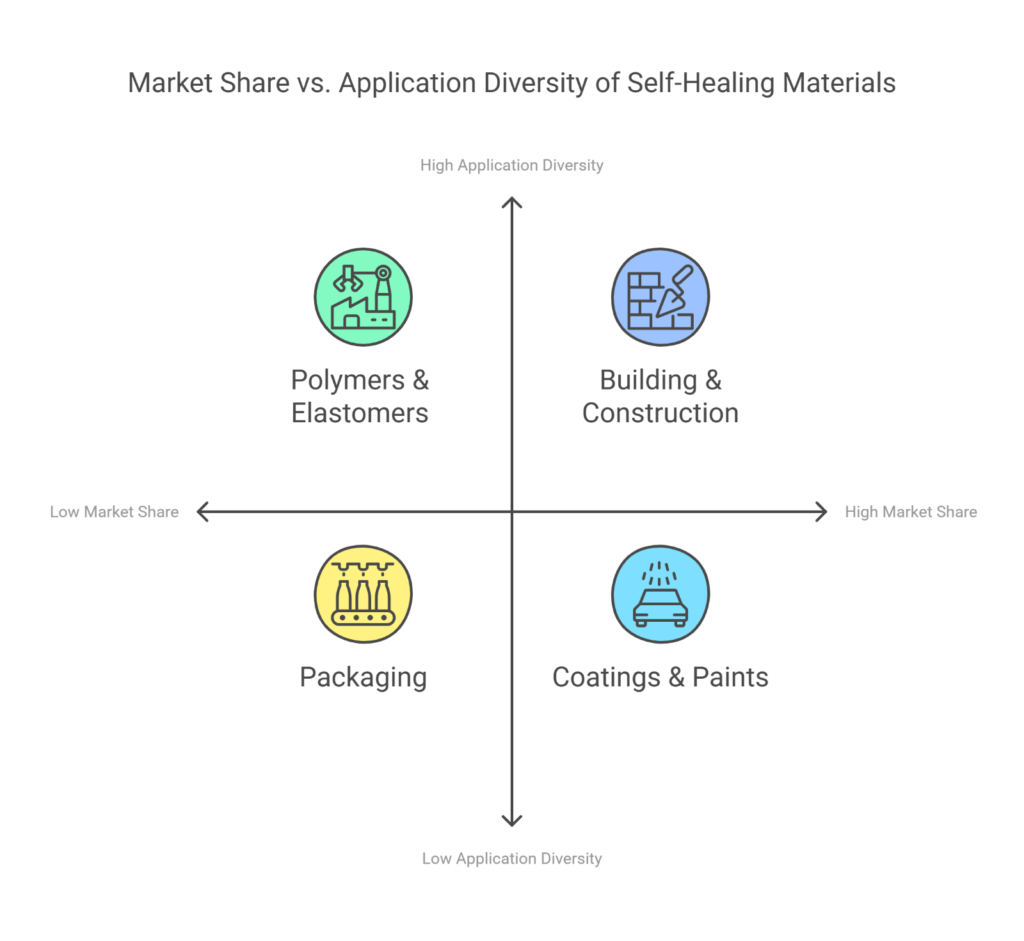

Self-healing materials are carving their niche across multiple industries, each driven by unique functional needs and innovation goals. Below is a sector-wise outlook on current adoption trends and future potential:

- Coatings & Paints: Currently a dominant segment, driven by automotive, aerospace, and construction applications seeking enhanced surface protection and longevity.

- Polymers & Elastomers: High potential in electronics, consumer goods, and medical devices due to their versatility and the ability to incorporate various healing mechanisms.

- Concrete: Growing interest for infrastructure projects aiming to reduce long-term maintenance costs and improve structural integrity.

- Composites: Crucial for high-performance applications like aerospace and wind energy where reliability and lightweight strength are paramount.

- Packaging: Emerging interest in self-healing films or layers to improve barrier properties and potentially reseal minor punctures, reducing spoilage or contamination (though cost is a factor).

- Medical & Pharma: Strong potential for implants, drug delivery systems, and even wound dressings, focusing on biocompatibility and long-term performance.

Trending Focus: Coatings and polymers currently see the most widespread research and commercial interest, but concrete and composites are rapidly gaining traction for large-scale applications. Electronics and medical fields represent high-value, future growth areas.

In a recent project, our market assessment and valuation services provided clients with a clear roadmap to commercializing self-healing material innovations in the coatings and paints sector.

Signicent’s team combined market intelligence with patent portfolio analysis to assess how top players are positioning their IP in the self-healing composites space.

Leading Companies:

These organizations are at the forefront of developing and commercializing self-healing materials across various sectors.

Recently, Signicent successfully supported a client in integrating self-healing materials into advanced consumer electronics. Our services included technology scouting, IP analysis, and material benchmarking to identify cutting-edge self-repairing polymers. We also conducted a white space analysis to uncover innovation gaps and future-ready opportunities in smart device protection and longevity.

If you wish to access the complete white space analysis and tailored innovation roadmap, feel free to contact us for in-depth insights and strategic solutions.

Future Outlook and Sustainability

Self-healing materials are rapidly shifting from experimental science to real-world application, redefining the future of material durability and circular innovation. As industries push toward eco-conscious design and longevity, these materials are emerging as a key enabler of sustainable transformation. We supported scale-up initiatives by conducting supplier search exercises to identify sustainable raw material providers for eco-conscious healing polymers. In the years ahead, we can expect breakthroughs in autonomous healing mechanisms, bio-based composites, and multi-cycle recovery systems that extend product lifecycles and reduce dependence on virgin resources.

Despite challenges like scalability, affordability, regulatory standards, and recyclability at end-of-life, the momentum is strong. Self-healing materials are likely to be a pillar in sustainable manufacturing and smart product development as investment grows, academic-industry alliances emerge, and low-waste solutions become increasingly sought for worldwide.

Their evolution aligns perfectly with global sustainability goals—delivering not just material integrity, but environmental resilience.

Frequently Asked Questions (FAQs)

Q1: What exactly are self-healing materials?

A: They are materials able to autonomously repair damage (such as scratches or cracks) on their own, generally without the need for external assistance, similar to biological healing.

Q2: Are self-healing materials actually used in products today?

A: Yes, some applications exist, particularly in specialized coatings (like for cars) and are emerging in areas like construction (concrete) and electronics. Widespread use is still developing but growing.

Q3: What are the main benefits of using them?

A: Key benefits include longer product lifespans, reduced need for repairs and replacements, lower maintenance costs, increased safety and reliability, and significant potential for waste reduction and sustainability.

Q4: Are self-healing materials expensive?

A: Currently, they can be more expensive to produce than traditional materials. However, their extended lifespan and reduced maintenance can lead to lower overall lifetime costs in many applications. Costs will be cover to fall as technology evolves, and production expands.

Q5: How do self-healing materials help the environment?

A: By making products last longer, they reduce the need to manufacture replacements, which saves raw materials, energy, and water. This also leads to less waste ending up in landfills and potentially reduces pollution associated with both manufacturing and disposal.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Patent Landscape

- Patent Portfolio Analysis

- Patent Invalidity Search

- Patent Licensing Services

- Freedom to operate (FTO)

- Chemical Structure Search

- Design Patent Search

- Technology Scouting

- Technology Landscape Analysis

- Technology gap analysis

- Technology Intelligence

- Market Research

- Bio Sequence Search

- Manufacturers Search/ Supplier search

Elevate your Innovation and Research with Signicent’s cutting-edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.