In the global automotive industry, Tyres are essential in the automotive industry, but their environmental impact remains a major concern. Millions of discarded tyres contribute to landfills, microplastic pollution, and rising carbon emissions. Did you know that over 1 billion tyres are discarded each year, adding to environmental waste? and Traditional tyre manufacturing relies on petroleum-based materials, making recycling costly and inefficient. Additionally, high rolling resistance leads to increased fuel consumption, further worsening emissions.

To address these challenges, technology is transforming the tyre industry. AI-driven monitoring, IoT-enabled sensors, and self-healing materials are improving tyre durability, efficiency, and recyclability. Companies are also developing eco-friendly alternatives like dandelion rubber and recycled materials to reduce waste and reliance on non-renewable resources. These innovations enhance road safety, lower emissions, and improve fuel efficiency.

As the demand for sustainable mobility grows, smart and green tyres are becoming a key solution. With advancements in materials and technology, the industry is shifting towards eco-friendly solutions that balance performance, safety, and environmental responsibility.

Signicent’s Patent Landscape Analysis helps companies study tyre materials, sensors, and self-repairing rubber, ensuring they understand new technologies and trends in the tyre industry.

Can a tyre be both smart and green?

Absolutely! The future of tyres lies in merging intelligence with sustainability by integrating AI-driven monitoring, eco-friendly materials, self-regulating inflation, and IoT-enabled connectivity for enhanced efficiency and reduced environmental impact. Here’s a detailed explanation of how these innovations are shaping the tyre industry:

- AI & IoT Integration: Smart tyres use embedded sensors to track pressure, temperature, and wear in real-time, ensuring optimal performance and safety.

- Eco-Friendly Materials: Tyres are now made from dandelion rubber, recycled carbon black, and silica-based compounds, reducing reliance on petroleum-based materials.

- Self-Healing Technology: Innovations in self-repairing materials enable tyres to automatically seal punctures, extending lifespan and reducing waste.

- Adaptive Performance: AI-driven systems adjust tyre pressure based on road conditions, optimizing grip, fuel efficiency, and energy consumption in electric and conventional vehicles.

- Biodegradable Components: Researchers are developing tyres with materials that safely decompose at the end of their lifecycle, reducing landfill waste.

- Fuel Efficiency & Emission Reduction: Low rolling resistance tyres help lower CO₂ emissions and extend EV battery life, making transportation more sustainable.

With Patent Portfolio Analysis, businesses can review their patents on AI-based tyres, pressure control, and recycled rubber, ensuring their ideas are well-protected and valuable.

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

Table: Key Players and Their Innovations

| Company | Innovation | Technology | Impact |

| Michelin | Self-Healing Tyres | Advanced materials that automatically repair small punctures. | Extends tyre lifespan, reduces waste, and lowers maintenance costs. |

| Bridgestone | Smart Strain Sensor | IoT-enabled device tracks strain, pressure, temperature, and wear in real-time. | Enhances safety, performance, and fuel efficiency. |

| Goodyear | Sight-Line Technology | AI and machine learning to predict maintenance needs and improve efficiency. | Ideal for autonomous vehicles, reduces downtime, and improves performance. |

| Continental | Dandelion Rubber | Replace petroleum-based rubber with renewable dandelion rubber. | Reduces reliance on non-renewable resources and promotes sustainability. |

| SMART Tire Co. | Airless Tyres | Shape memory alloys eliminate the risk of punctures. | Increases durability and reduces waste. |

| Tyre Collective | Recycling End-of-Life Tyres | Convert old tyres into reusable materials like carbon black and oil. | Promotes a circular economy and reduces environmental waste. |

Our Patent Invalidity Search checks if patents in eco-friendly tyres, silica compounds, and self-repairing treads can be challenged, helping companies avoid legal risks.

Global Challenges in the Automotive Tyres Market

What Are Industries and Consumers Facing?

The tyre industry faces several critical challenges that demand innovative solutions, including waste management, recycling inefficiencies, high rolling resistance, safety concerns, and the need for sustainable, high-performance materials.

Consumer Challenges:

- Frequent Tyre Replacement: Traditional tyres wear out faster due to friction and road conditions, increasing maintenance costs and causing inconvenience for vehicle owners.

- Fuel Efficiency Issues: High rolling resistance in conventional tyres increases energy consumption, leading to more fuel expenses for drivers and reduced mileage for electric vehicles.

- Safety Risks: Poor traction on wet, icy, and uneven terrains results in skidding, longer braking distances, and a higher risk of accidents, compromising road safety.

- Limited EV Tyre Options: Many tyres are not optimized for electric vehicles, affecting performance, range, and durability, making it difficult for EV owners to find efficient options.

- Lack of Sustainable Choices: Environmentally friendly and recyclable tyres remain expensive and less accessible, limiting consumer adoption despite the growing demand for greener alternatives.

Industry Challenges:

- Environmental Waste Management: Over 1 billion tyres reach the end of their life annually, with most ending up in landfills or incineration, releasing toxic pollutants.

- Recycling Limitations: Tyres are made from complex materials like synthetic rubber, steel, and fabric, making recycling processes costly, inefficient, and challenging for manufacturers.

- Regulatory Compliance: Stricter global emissions and sustainability regulations push manufacturers to adopt greener production methods while balancing costs and maintaining product performance.

- Raw Material Dependency: Tyre production heavily depends on petroleum-based materials and synthetic compounds, increasing costs, supply chain risks, and environmental impact.

- EV Compatibility Demand: Electric vehicles require low-rolling-resistance, high-durability tyres to optimize battery efficiency, creating manufacturing challenges in material selection and design.

These challenges highlight the urgent need for smarter and greener tyre solutions that enhance durability, improve efficiency, reduce environmental impact, and align with evolving mobility demands.

Innovations in Smart and Green Tyres

The tyre industry is undergoing a transformation with groundbreaking innovations from leading players and emerging startups. As environmental concerns and safety demands rise, companies are investing in sustainable and intelligent tyre technologies to tackle key challenges.

How Are Innovations Reshaping Tyres?

Smart and green tyre advancements are addressing critical issues like environmental waste, road safety, and fuel efficiency. From self-healing materials to IoT-enabled sensors, these innovations enhance performance while promoting sustainability. Industry giants like Michelin, Bridgestone, Goodyear, and Continental are driving change, while startups are introducing fresh, disruptive solutions.

Our FTO Search Services ensure that companies launching smart tyres, rolling resistance solutions, or pressure control systems do not infringe on existing patents.

Technologies in Smart and Green Tyres

Here’s a detailed breakdown of key technologies, their explanations, diagrams, companies using them, and their benefits. Each technology is explained in words, followed by a diagram, companies using it, and the benefits.

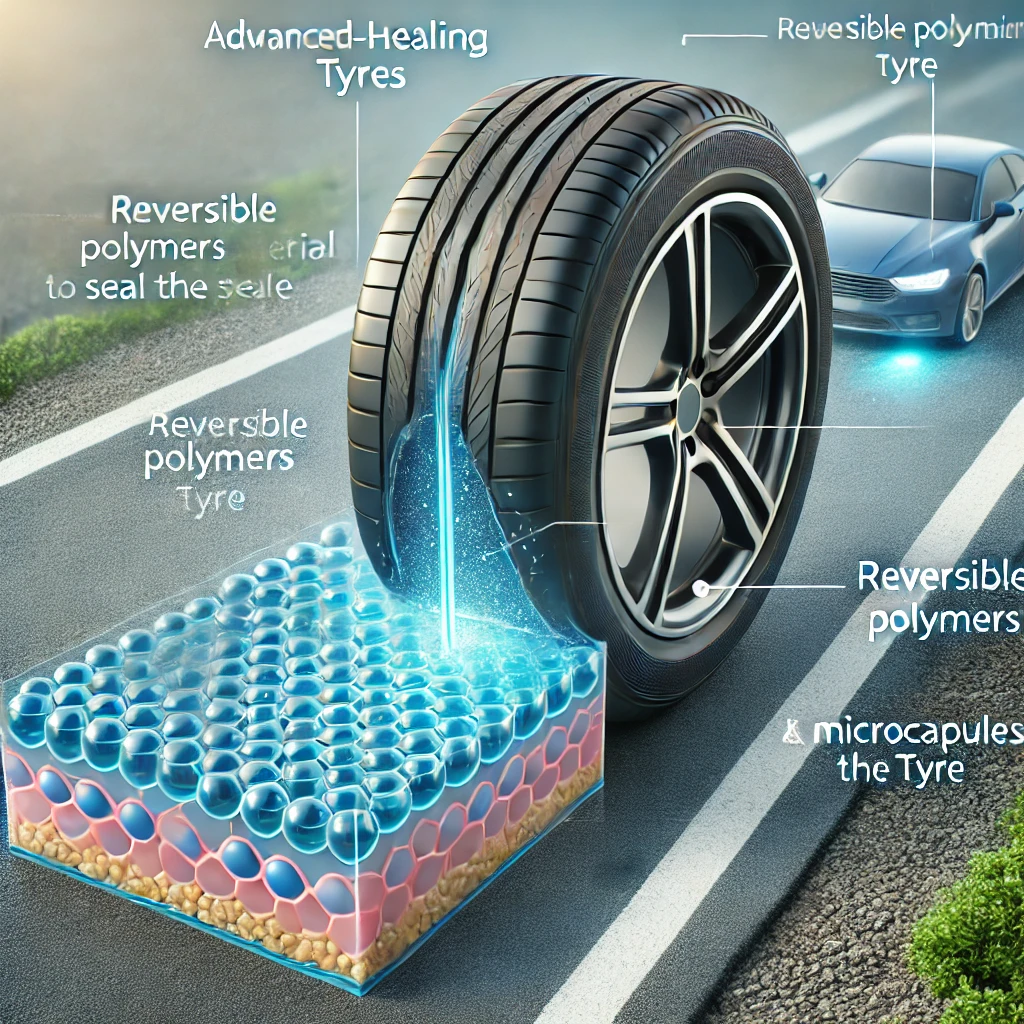

1. Self-Healing Tyres

Self-healing tyres use advanced materials like reversible polymers or microcapsules to automatically repair small punctures. When damaged, the material flows into the hole, sealing it and preventing air loss, extending tyre lifespan and reducing waste.

Companies Using This Technology:

- Michelin: Innovating self-healing tyres for commercial vehicles, aiming to reduce maintenance costs, enhance durability, and minimize environmental waste.

- Pirelli: Advancing self-healing materials for high-performance tyres, ensuring longevity, improved safety, and optimized driving experiences.

Benefits:

- Reduces the need for frequent repairs and replacements.

- Extends tyre lifespan, lowering costs and environmental impact.

- Enhances safety by preventing sudden air loss.

2. IoT-Enabled Smart Sensors

IoT-enabled sensors embedded in tyres monitor pressure, temperature, strain, and tread wear in real-time. Data is sent to the vehicle’s system or a smartphone app, improving safety, performance, and maintenance efficiency.

Companies Using This Technology:

- Bridgestone: Smart Strain Sensor technology offers real-time tyre health monitoring, improving vehicle safety, performance, and predictive maintenance.

- Goodyear: SightLine technology integrates AI and IoT to analyze tyre conditions, predicting maintenance needs for enhanced efficiency.

Benefits:

- It improves fuel efficiency and reduces emissions.

- Enhances safety by alerting drivers to potential issues.

- Reduces downtime and maintenance costs.

3. Airless Tyres

Airless tyres use a unique structure made from shape memory alloys or reinforced polymers to support vehicle weight without air. This eliminates punctures and blowouts, making them ideal for rugged terrains and heavy-duty use.

Companies Using This Technology:

- Michelin: Uptis (Unique Puncture-Proof Tire System) airless tyres, designed for passenger vehicles, enhance durability, sustainability, and eliminate flat tyres.

- Hankook: Developing airless tyres specifically for urban mobility, ensuring safety, reliability, and reduced environmental impact.

Benefits:

- Eliminates the risk of punctures and blowouts.

- Reduces waste and maintenance costs.

- Ideal for EVs and autonomous vehicles.

With Chemical Structure Search, we study materials like bio-based rubber, new tyre compounds, and advanced treads, helping companies find better alternatives for manufacturing.

4. Dandelion Rubber (Taraxagum)

Dandelion rubber is extracted from Russian dandelion roots, offering a sustainable alternative to petroleum-based rubber. It requires less land and water to cultivate, reducing environmental impact and reliance on non-renewable resources.

Companies Using This Technology:

- Continental: The Taraxagum project develops tyres using dandelion-derived rubber, providing a sustainable alternative to traditional rubber while reducing environmental impact.

- Sumitomo Rubber: Conducting research on dandelion-based rubber to create eco-friendly tyres, reducing dependency on conventional rubber plantations and enhancing sustainability.

Benefits:

- Reduces reliance on petroleum-based materials.

- Promotes sustainable farming practices.

- Lowers the carbon footprint of tyre production.

Our Patent Design Search helps companies protect ideas related to tread designs, tyre durability, and aerodynamics, ensuring they stay competitive in the industry.

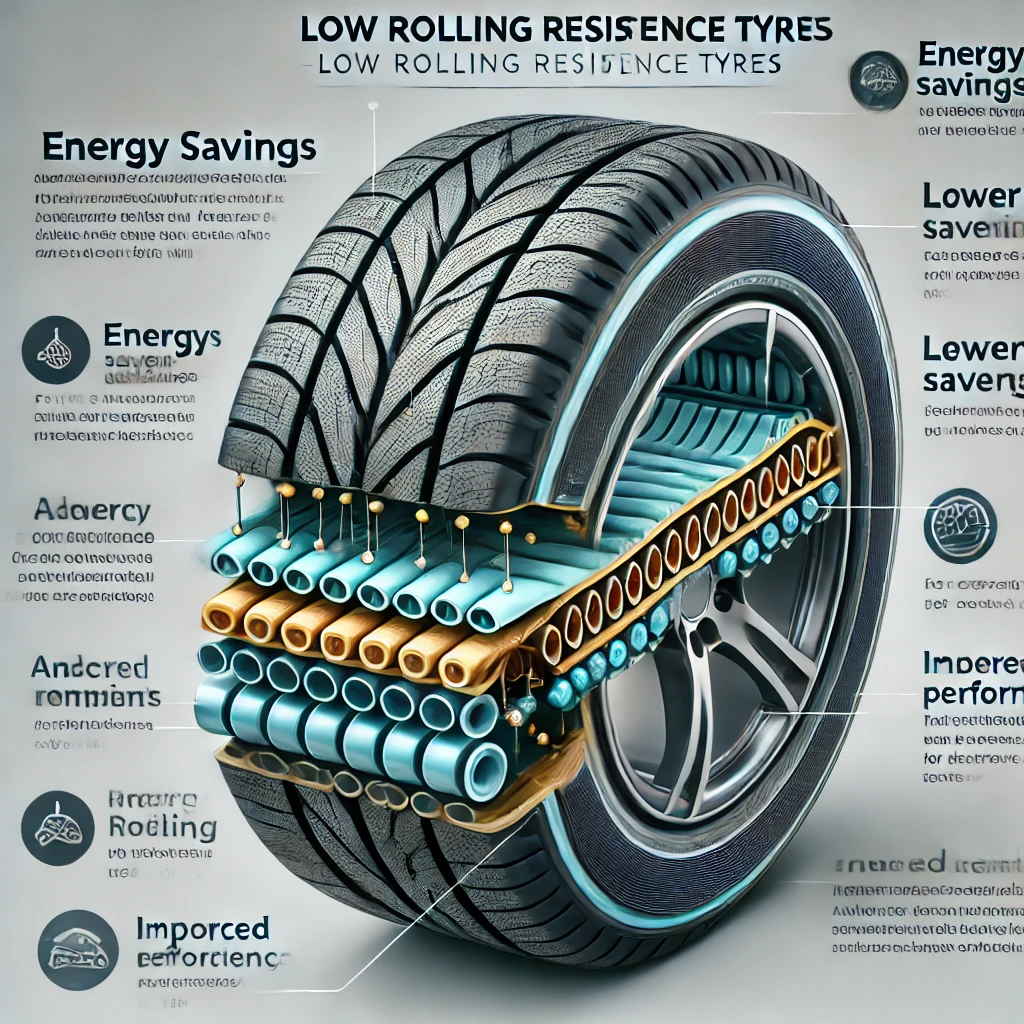

5. Low Rolling Resistance Tyres

Low rolling resistance tyres use special tread patterns and materials to reduce the energy required to move the vehicle. This improves fuel efficiency and reduces CO₂ emissions, making them ideal for EVs.

Companies Using This Technology:

- Bridgestone: Ecopia tyres improve fuel efficiency by up to 10%, reducing carbon emissions and enhancing sustainability without compromising performance.

- Yokohama: Developing low rolling resistance tyres specifically for hybrid and electric vehicles, optimizing energy consumption while maintaining superior performance and durability.

Benefits:

- It improves fuel efficiency and reduces emissions.

- Extends battery range for EVs.

- Lowers operating costs for drivers.

6. Tyre Recycling and Circular Economy

Tyre recycling uses processes like pyrolysis to break down old tyres into reusable materials like carbon black, oil, and steel. These materials are used to produce new tyres or other products, reducing waste.

Companies Using This Technology:

- Michelin: Partnered with Enviro to develop pyrolysis-based recycling, transforming end-of-life tyres into reusable raw materials for sustainable production.

- Apollo Tyres: Investing in advanced recycling technologies to integrate reclaimed rubber and reduce environmental impact in tyre manufacturing processes.

Benefits:

- Reduces landfill waste and environmental pollution.

- Promotes a circular economy by reusing materials.

- Lowers the carbon footprint of tyre manufacturing.

Through Technology Landscape Analysis, companies can study biodegradable tyre materials, recycled compounds, and smart sensors, understanding industry changes and how to improve products.

Benefits in the Sustainability POV

Smart and green tyres provide substantial sustainability benefits, reducing emissions, minimising waste, enhancing efficiency, and supporting eco-friendly mobility solutions for a greener automotive future.

- Reduced Carbon Footprint: Low rolling resistance tyres enhance fuel efficiency by minimizing energy loss, directly cutting emissions and promoting eco-friendly transportation.

- Less Waste: Self-healing materials and advanced recycling technologies extend tyre lifespan, significantly reducing landfill waste and environmental pollution.

- Renewable Materials: Dandelion rubber, bio-based compounds, and recycled materials decrease dependency on petroleum-based products, fostering sustainable tyre manufacturing.

- Safer Roads: Real-time monitoring systems and adaptive tyre technologies enhance traction, stability, and safety, especially in adverse weather conditions.

- Support for EVs: Specialised tyres optimize battery efficiency, extending driving range and accelerating the global shift toward electric vehicles and clean mobility solutions.

These benefits position smart and green tyres as a cornerstone of sustainable mobility, reducing emissions, waste, and resource dependency while enhancing safety and efficiency.

Through Market Assessment and Valuation, we evaluate business opportunities in smart tyres, sustainable materials, and tyre monitoring, helping companies make better investment decisions.

Market Outlook for the Global Smart and Green Tyres Industry

The global tyre market is witnessing significant growth, driven by rising demand for sustainable, smart, and high-performance tyres across regions. Asia-Pacific leads production and consumption, while North America and Europe focus on advanced, eco-friendly technologies.

As per Signicent’s market research, the global automotive tyre market is projected to reach significant value ranges, driven by rising demand for sustainable, smart, and high-performance tyres. The market’s growth is fueled by increasing adoption of green and intelligent tyre solutions worldwide.

Signicent has helped clients adopt smart and green tyre technologies by providing technology scouting and sustainability consulting. By identifying emerging innovations, Signicent has supported companies in improving tyre durability, fuel efficiency, and recyclability. For instance, Signicent assisted a tyre manufacturer in developing low-rolling-resistance tyres that enhanced fuel efficiency and reduced emissions. In another case, Signicent helped a startup integrate IoT-enabled sensors for real-time tyre monitoring, improving safety and performance.

Our Technology Gap Analysis identifies missing advancements in energy-saving tyres, traction control, and tyre monitoring, helping businesses develop better products for the market.

If you want full access to the document and white space analysis, you can contact us for detailed insights and related services.

Future Outlook

By 2030 and beyond, the tyre industry will be transformed by smart technology, eco-friendly materials, and circular economy principles. We can expect tyres made from sustainable, bio-based compounds, equipped with real-time monitoring sensors for enhanced safety and efficiency. Airless and self-repairing tyres could become mainstream, reducing maintenance needs and extending lifespan. The integration of AI and IoT will optimize tyre performance, minimizing waste and maximizing fuel efficiency. As regulations push for lower carbon footprints, manufacturers will invest heavily in recycling, renewable materials, and energy-efficient production processes. The future of tyres is not just about driving—it’s about creating a cleaner, smarter, and more connected world.

FAQs on the Future of Tyre Innovations

Can tyres become fully sustainable and recyclable without compromising performance?

Yes, advancements in materials like bio-based rubber, recycled carbon black, and biodegradable polymers are making tyres more sustainable without affecting durability. Companies are also developing circular economy models to ensure complete recyclability.

How are AI and IoT enhancing tyre safety and efficiency on the road?

AI-driven smart sensors monitor tyre pressure, tread wear, temperature, and road conditions in real time. IoT integration allows predictive maintenance, reducing accidents, improving fuel efficiency, and extending tyre lifespan.

What role do alternative materials like dandelion rubber play in reducing petroleum dependency?

Dandelion rubber, sourced from Taraxacum kok-saghyz plants, offers a renewable and locally grown alternative to synthetic rubber, reducing reliance on petroleum-based production and cutting environmental impact.

Can smart tyres help reduce fuel consumption and carbon emissions in electric and conventional vehicles?

Yes, low rolling resistance tyres reduce energy loss, leading to better fuel efficiency in conventional cars and extended battery range in EVs. Smart sensors optimize tyre pressure, further lowering carbon emissions.

Which industries will benefit most from smart tyre technology—automotive, logistics, or aviation?

All three industries benefit, but logistics sees the most impact. Fleet operators can use real-time data for predictive maintenance, reducing downtime and operational costs. Aviation benefits from intelligent wear detection, while the automotive sector gains better efficiency and safety features.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Patent Landscape

- Patent Portfolio Analysis

- Patent Invalidity Search

- Patent Licensing Services

- Freedom to operate (FTO)

- Chemical Structure Search

- Design Patent Search

- Technology Scouting

- Technology Landscape Analysis

- Technology gap analysis

- Technology Intelligence

- Market Research

- Bio Sequence Search

- Manufacturers Search/ Supplier search

Elevate your Innovation and Research with Signicent’s cutting edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.