In the ever-evolving realm of 3D printing or additive manufacturing, the innovation in chemicals and materials is driving the industry. This transformative technology, which started as a prototyping tool, has now permeated various industries, enabling the creation of complex geometries and bespoke designs with remarkable precision and efficiency. The key to these advancements lies in the development and utilization of innovative chemicals and materials specifically designed for additive manufacturing.

Signicent’s active participation in technology gap analysis is illustrated by its ongoing research and development efforts. The goal is to provide effective sustainable 3D printing materials that are personalized to industry needs, with innovative solutions and long-term advantages for enhanced manufacturing and environmental impact.

Challenges in 3D Printing:

- While the range of materials for 3D printing is expanding, ensuring compatibility and consistency across different materials remains a challenge.

- Achieving high precision and quality in printed parts, especially with complex geometries and fine details, can be difficult due to limitations in current printing technologies and materials.

- Despite advancements in sustainable materials, the environmental footprint of 3D printing, including energy consumption and waste management, needs continuous improvement.

The Evolution of 3D Printing Materials

The initial phases of 3D printing primarily utilized polymers due to their ease of use and cost-effectiveness. However, as technology matured, the demand for diverse materials that could cater to specific industry needs became evident. This led to the development of advanced materials that offer superior mechanical properties, thermal stability, and chemical resistance.

Polymers: The Backbone of 3D Printing

Polymers continue to be a cornerstone in 3D printing materials. Among the most commonly used are:

- PLA (Polylactic Acid): A biodegradable thermoplastic derived from renewable resources like corn starch. It is known for its ease of printing, affordability and environmental friendliness.

- ABS (Acrylonitrile Butadiene Styrene): Renowned for its strength, durability and heat resistance, making it suitable for functional parts and consumer products.

- PETG (Polyethylene Terephthalate Glycol): Combines the ease of use of PLA with the strength of ABS. It is known for its chemical resistance and flexibility.

High-Performance Polymers

To meet the demands of high-performance applications, advanced polymers such as PEEK (Polyether Ether Ketone) and PEI (Polyetherimide) have been developed. These materials are known for their exceptional thermal and chemical resistance, making them suitable for aerospace, automotive and medical applications.

Metals: Expanding the Horizons

Metal 3D printing, also known as metal additive manufacturing, has revolutionized industries by enabling the production of high-strength, complex metal parts. The most common metals used in this process include:

- Stainless Steel: Known for its corrosion resistance and strength, it is widely used in aerospace, automotive, and medical devices.

- Titanium: Offers a high strength-to-weight ratio and excellent biocompatibility, making it ideal for aerospace and biomedical applications.

- Aluminum: Valued for its lightweight and thermal conductivity, it is extensively used in automotive and aerospace industries.

- Inconel: A nickel-chromium-based superalloy known for its excellent oxidation and corrosion resistance at high temperatures, ideal for aerospace and high-performance engineering.

Ceramics: Pushing the Boundaries

Ceramic 3D printing is another frontier, offering materials with unique properties such as high hardness, temperature resistance, and chemical stability. Common ceramics used in additive manufacturing include:

- Silicon Carbide (SiC): Known for its high thermal conductivity, low thermal expansion, and excellent wear resistance.

- Alumina (Al2O3): Offers high hardness, corrosion resistance, and electrical insulation properties.

- Zirconia (ZrO2): Known for its high fracture toughness and thermal expansion, making it suitable for medical and dental applications.

Composites: Combining the Best of Both Worlds

Composite materials are designed to leverage the benefits of multiple materials, offering enhanced mechanical properties and functionality. Common composites in 3D printing include:

- Carbon Fiber Reinforced Polymers: Known for their high strength-to-weight ratio and rigidity, these are ideal for aerospace and automotive applications.

- Glass Fiber Reinforced Polymers: Provide excellent strength and durability, making them suitable for various industrial applications.

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

Photopolymers: Light-Curing Innovation

Photopolymers are used in stereolithography (SLA) and digital light processing (DLP), where liquid resins are cured using light. These materials offer high precision and smooth surface finishes, making them ideal for detailed prototypes and dental applications. Common types include:

- Standard Resins: Used for general-purpose prototyping with good dimensional accuracy.

- Tough Resins: Designed for functional parts requiring impact resistance and strength.

- Flexible Resins: Used for parts that need flexibility and elasticity.

Chemical Innovations Driving Material Performance

The development of innovative chemicals plays a crucial role in enhancing the performance of 3D printing materials. These innovations are aimed at improving print quality, mechanical properties, and the environmental impact of the materials.

Functional Additives

Functional additives are chemicals incorporated into 3D printing materials to enhance their properties. These include:

- Stabilizers: Improve the thermal stability and lifespan of the material.

- Plasticizers: Increase the flexibility and workability of the material.

- Colorants: Provide a wide range of colors without compromising material properties.

Biocompatible Materials

The development of biocompatible materials is particularly important for medical and dental applications. These materials are designed to be safe for contact with biological tissues and include:

- Biocompatible Polymers: Such as medical-grade PLA and polycaprolactone (PCL), used in implants and scaffolds for tissue engineering.

- Biocompatible Metals: Including titanium and tantalum, used in orthopedic implants and dental prosthetics.

Sustainable and Eco-Friendly Materials

There is a growing emphasis on sustainability in 3D printing. Innovations in eco-friendly materials aim to reduce the environmental impact of additive manufacturing. These include:

- Recycled Polymers: Materials derived from recycled plastics, contributing to a circular economy.

- Bio-based Polymers: Made from renewable resources, offering an environmentally friendly alternative to traditional plastics.

Applications and Industry Impact

The advancements in 3D printing materials and chemicals have led to transformative impacts across various industries.

Healthcare and Biomedical

In healthcare, 3D printing is used for creating customized implants, prosthetics, and surgical guides. Biocompatible materials enable the production of patient-specific medical devices, improving treatment outcomes and reducing recovery times.

Aerospace and Automotive

The aerospace and automotive industries benefit from the ability to create lightweight, high-strength components with complex geometries. Metal and composite materials are particularly valuable for their performance in demanding environments.

Consumer Goods and Electronics

In the consumer goods sector, 3D printing allows for rapid prototyping and the creation of intricate designs. Polymers and photopolymers are commonly used to produce parts with high detail and quality.

Construction and Architecture

Additive manufacturing is revolutionizing construction by enabling the creation of complex structures and components. Concrete and other advanced materials are used to construct buildings and infrastructure with unique architectural features.

Through comprehensive technology intelligence, we strategically identify areas where our clients can strengthen their competitive edge and capitalize on emerging opportunities.

Market Research:

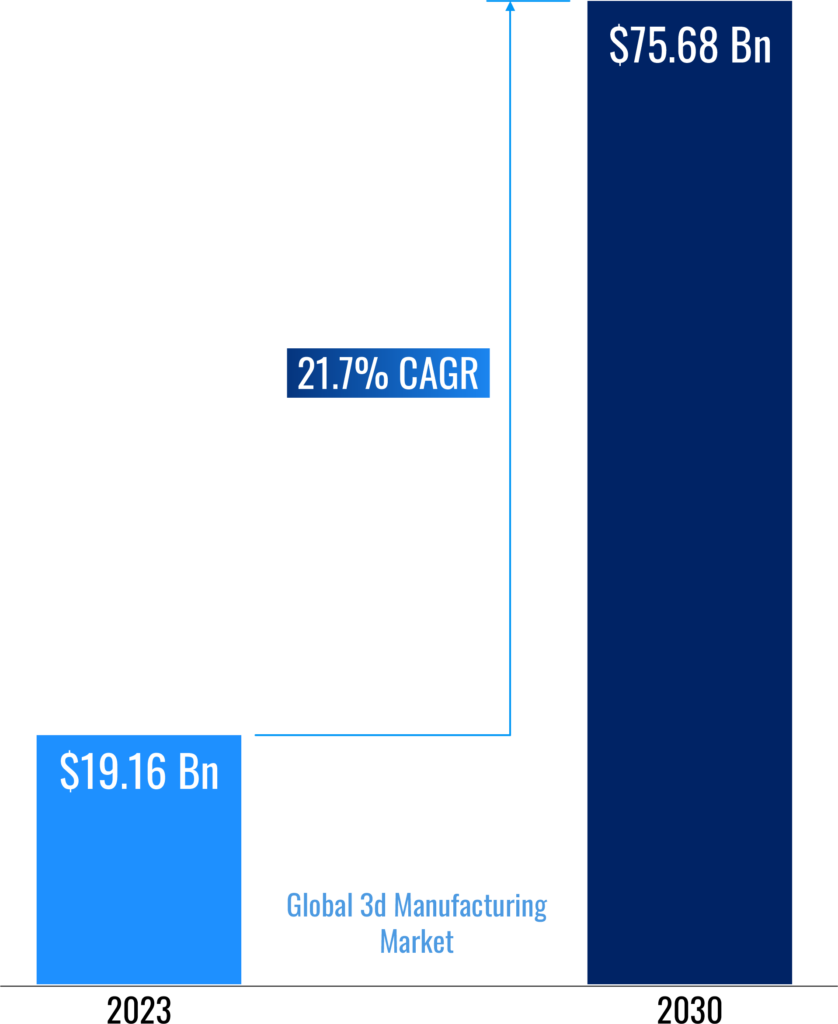

As per Signicent’s Market Intelligence, the global market for Sustainable 3D Printing is likely to reach values in the ranges shown below.

Key Players:

According to Signicent’s Market Intelligence, these are the leading giants and innovative startups in the sustainable 3D printing sector:

Leading Giants:

Innovative Startups:

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Technology Intelligence

- Market Research

- Patent Landscape

- Technology gap analysis

- Design Patent Search

- Portfolio Analysis

- Freedom to operate

- Bio Sequence Search

- Innovation pipeline identification

- Chemical Structure Search

- Patent Invalidity Search

- Manufacturers Search/ Supplier search

- Patent Licensing Services

Elevate your Innovation and Research with Signicent’s cutting edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.