Abstract:

AI is redefining the manufacturing sector by enhancing efficiency, improving quality control, and optimizing processes. This document explores the various applications of AI in manufacturing, the challenges faced when integrating human and machine collaboration, and the innovations that are shaping the future of the industry. By conducting a technology landscape analysis, we gain a clearer understanding of the evolving trends, emerging technologies, and strategic opportunities driving this transformation. We will also discuss the benefits of AI, market outlook, key players, and significant contributions to the manufacturing landscape.

Introduction

The manufacturing industry is undergoing a significant transformation driven by advancements in technology, particularly Artificial Intelligence (AI). From defect detection to predictive analytics, AI is reshaping how manufacturers operate, leading to increased efficiency and reduced costs. As industries strive to remain competitive in a rapidly evolving market, understanding the implications of AI in manufacturing becomes crucial.

As Industry 4.0 gains traction, AI is becoming integral to smart factories, enabling data-driven decision-making and facilitating seamless collaboration between humans and machines. The global market for AI in manufacturing is poised for significant growth, fueled by advancements in machine learning, computer vision, and the Internet of Things (IoT). However, Patent Invalidity Analysis plays a crucial role in assessing the validity of intellectual property rights in these emerging technologies, ensuring that businesses navigate legal complexities efficiently. This article delves into the challenges, innovations, and key players driving AI in manufacturing, offering valuable insights on how businesses can harness this transformative technology to stay ahead in an increasingly competitive market.

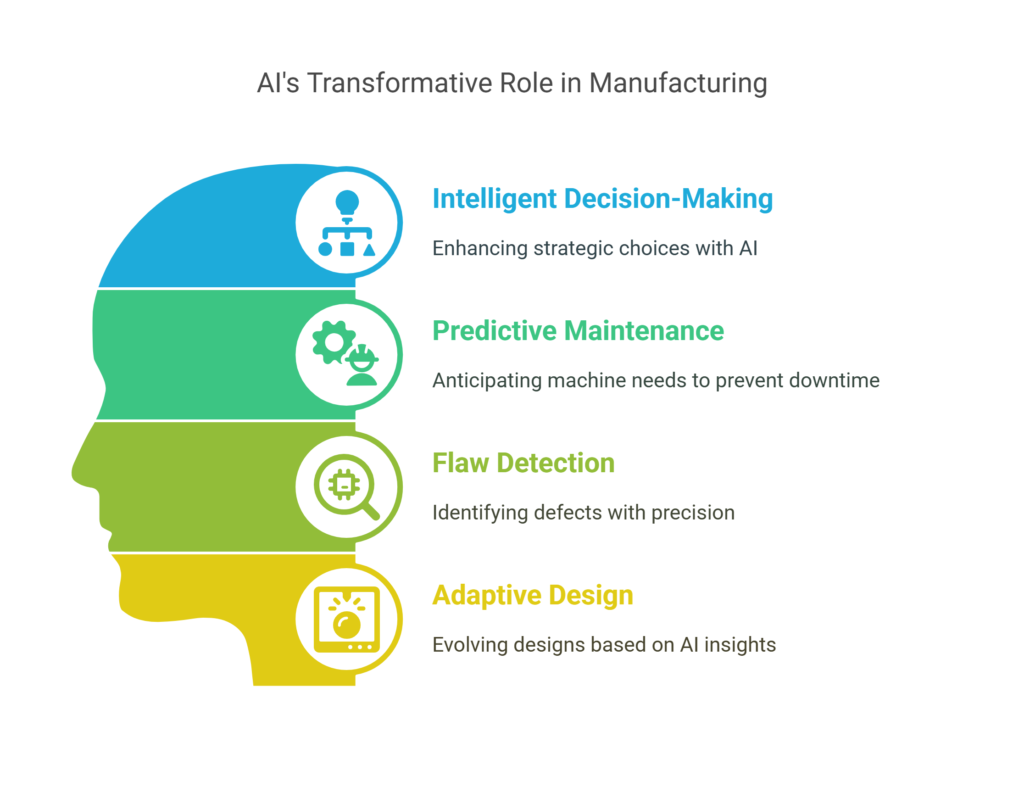

Can machines think like humans—and work even better?

As factories become smarter and more linked, technology such as AI is playing a critical role in altering the manufacturing landscape. AI is transforming every element of production, from intelligent decision-making to predictive maintenance, precise flaw detection, and adaptable design.

Instead of simply supporting human workers, AI anticipates demands, analyzes massive data sets, and optimizes operations in real time. With the ability to provide data-driven insights and increase operational efficiency, AI is swiftly demonstrating that it cannot only match but outperform human talents, enabling innovation, precision, and continuous improvement across industries.

Challenges Before AI in Manufacturing:

Before AI, manufacturing companies faced numerous challenges that hindered efficiency, quality, and productivity. These obstacles were largely driven by manual processes, lack of predictive tools, and limited data insights. Here are some of the key issues:

- Manual Processes: Manufacturing heavily relied on manual labor, resulting in inefficiencies, longer production cycles, and frequent errors. Human involvement slowed processes, leading to higher costs and delays.

- Reactive Maintenance: Maintenance was based on schedules or past issues, leading to unplanned downtime and expensive repairs. Predicting failures before they happened was nearly impossible without advanced tools.

- Quality Control: Quality checks were mostly done by workers, which resulted in human error. This led to inconsistent product quality and defects going unnoticed until later stages of production.

- Inconsistent Decision-Making: Manufacturing decisions were often made intuitively or based on outdated data, resulting in inefficiencies and missed opportunities. Without real-time analytics, decision-making was reactive rather than proactive.

- Limited Data Insights: Manufacturing lacked the technology to collect and analyze data in real time. This limited the ability to solve problems quickly and optimize processes for efficiency.

- Workforce Skill Gaps: Skilled workers were needed to manage increasingly complex machinery, but the workforce often lacked the required digital skills. Training and adapting to new technologies were a slow process.

Innovations Transforming Modern Manufacturing

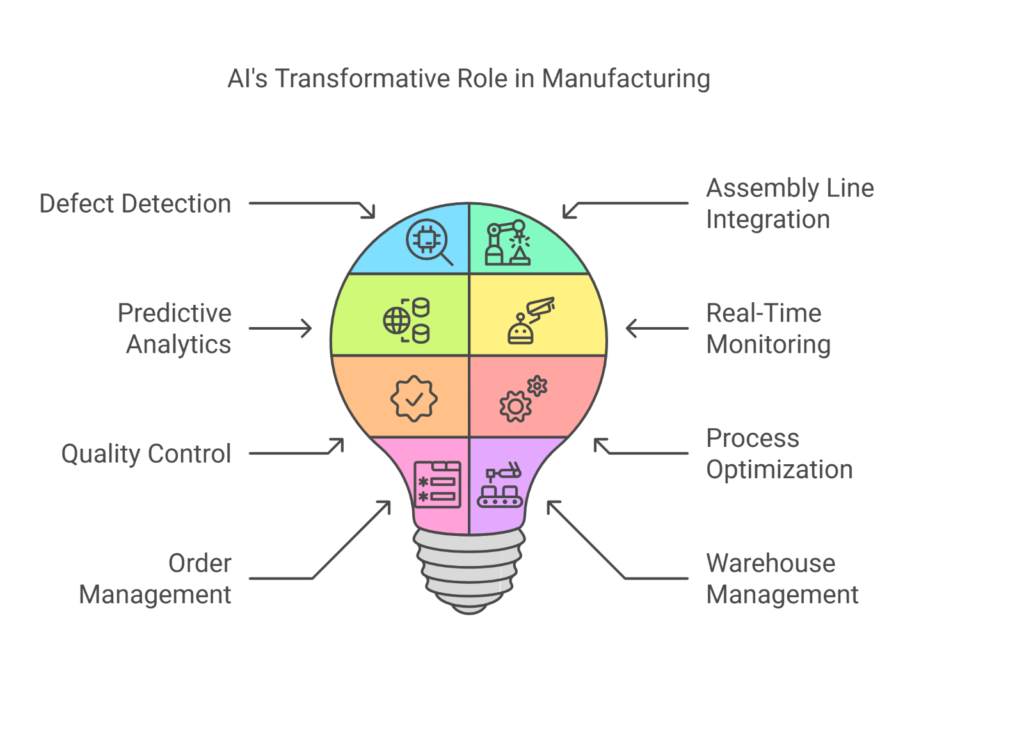

AI’s infusion into manufacturing is multidimensional. Here’s how it’s re-engineering each function:

- Defect Detection: Advanced ML and computer vision systems now analyze products in real-time, detecting the tiniest flaws invisible to the human eye, improving quality assurance and cutting costs.

- Assembly Line Integration: AI-driven assembly lines work with minimal human input, ensuring consistent, error-free operations while adapting to changes and enhancing throughput across varied production scenarios.

- Predictive Analytics: By analyzing sensor data, AI predicts potential equipment failures before they occur, reducing unplanned downtime, lowering repair costs, and boosting operational efficiency through proactive maintenance.

- Process Optimization: AI identifies inefficiencies in energy use, material waste, and machine usage; providing real-time recommendations to optimize cycle times, improve resource utilization, and increase overall yield.

- Real-Time Monitoring: AI-powered platforms enable continuous surveillance of production lines; flagging anomalies and enabling immediate corrective actions while supporting data-driven decision-making for enhanced operational control.

New-Age Solutions Reshaping the Manufacturing Ecosystem

Modern manufacturing integrates AI across all layers, from machinery to decision-making, optimizing operations and enhancing efficiency. To support innovation at the design stage, Patent Design Search plays a crucial role in identifying existing design patents, avoiding infringement, and inspiring novel, compliant product development.

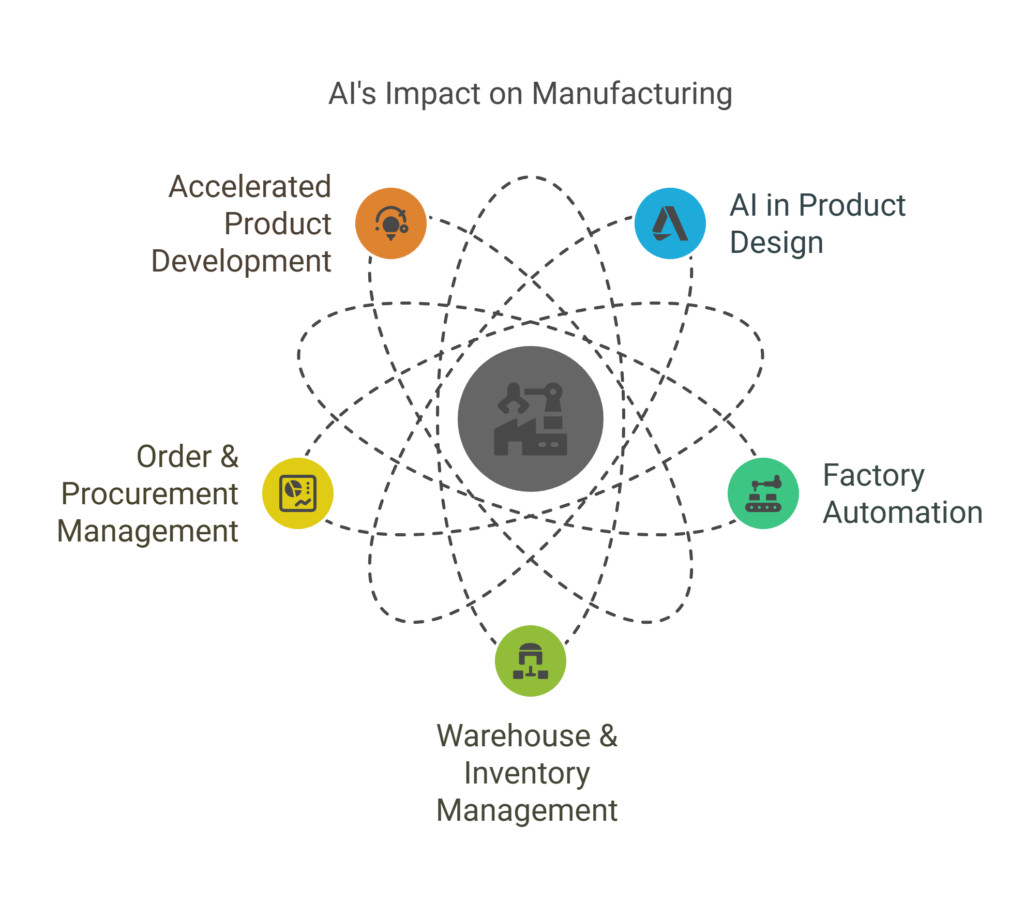

AI in Product Design

Generative AI design tools analyze material constraints, size, weight, and costs to generate optimized product prototypes. Engineers can test multiple iterations virtually, cutting design time drastically.

Factory Automation

AI enables seamless production scaling, anomaly detection, and centralized monitoring. Factories become self-adaptive systems with less human dependency and higher productivity.

Warehouse & Inventory Management

AI forecasts demand, tracks stock in real-time, and optimizes logistics. From automated sorting to cost-effective transportation, it ensures smarter supply chain decisions.

Order & Procurement Management

Smart dashboards use AI to estimate raw material costs, evaluate vendors, and manage procurement cycles. Manufacturers now make faster, cost-efficient purchasing decisions.

Accelerated Product Development

Data-driven simulations reduce the need for physical prototypes. AI shortens development cycles, reduces testing errors, and speeds up innovation-to-market timelines.

Benefits: How AI Can Streamline the Manufacturing Sector?

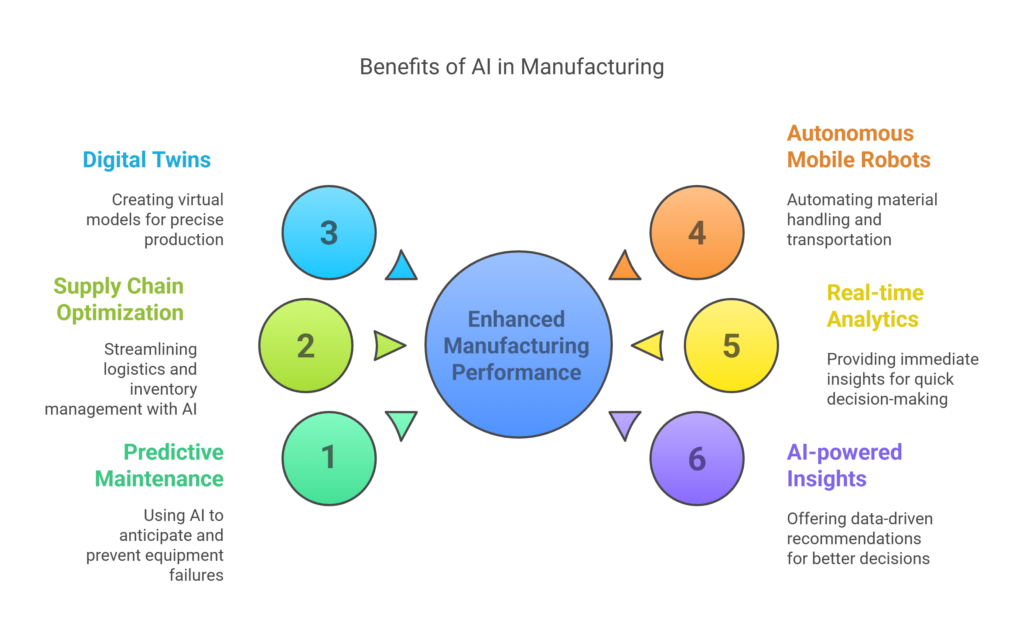

AI technologies, including Digital Twins, Autonomous Mobile Robots (AMRs), and AI-Based Supply Chain Optimization, are revolutionizing manufacturing. These advancements provide smarter operations, increased productivity, and improved cost management. Through AI, factories can embrace automation, enhance real-time decision-making, and optimize production efficiency.

By implementing these technologies, manufacturers gain significant advantages, such as achieving Freedom To Operate (FTO), reducing intellectual property risks, and ensuring that innovations comply with existing patents. These benefits support both strategic decisions and long-term sustainability in the rapidly evolving manufacturing sector.

- Reduced Operational Costs: AI-based predictive maintenance and supply chain optimization help cut down wastage and reduce overall expenses.

- Enhanced Product Quality: Digital Twins and AMRs ensure precision in production, minimizing defects and improving product consistency.

- Faster Time to Market: Real-time analytics and autonomous operations accelerate production timelines, reducing delays and improving customer satisfaction.

- Increased Operational Efficiency: AI tools automate routine tasks, enhancing workforce productivity and reducing human errors in daily operations.

- Improved Decision-Making: AI-powered insights help managers make quicker, data-driven decisions that are more accurate and efficient.

- Scalability and Flexibility: AI technologies allow manufacturers to scale operations quickly while adapting to fluctuating demands and market changes.

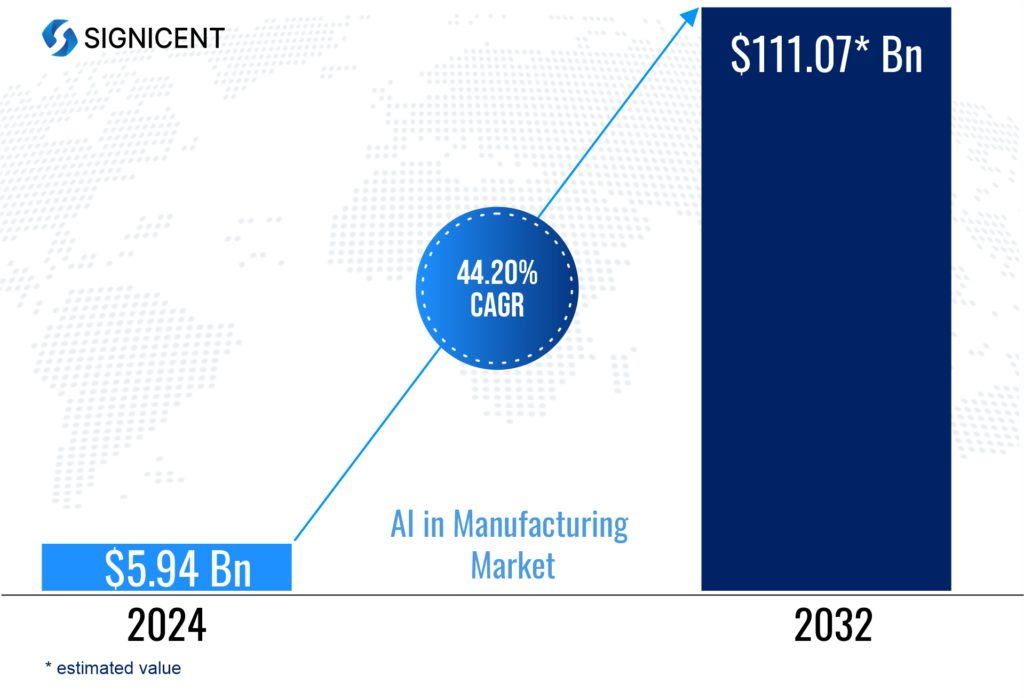

Market outlook: AI in manufacturing

The worldwide AI manufacturing market is on a transformational path. As per Signicent Market Research, the industry is expected to reach USD 111.07 billion by 2032, driven by significant improvements in industrial robotics, AI algorithms, and 5G-powered smart factories.

The surge is further accelerated by the rising adoption of predictive maintenance, AI-driven quality control, and digital twins across automotive, aerospace, electronics, and heavy industries, offering unmatched efficiency, reduced downtime, and smarter decision-making in production ecosystems. To navigate this evolving landscape, Market Assessment and Valuation become essential for understanding growth opportunities, estimating potential returns, and aligning innovations with market demand.

Here’s what’s accelerating this momentum:

- Smart Factories & Industry 4.0 Take Centre Stage

AI-driven automation, real-time analytics, and intelligent workflows are now the backbone of modern, agile manufacturing systems. - Predictive Maintenance Is Gaining Ground

AI detects failures before they strike—cutting downtime, reducing losses, and ensuring uninterrupted industrial performance. - Next-Gen Tech Stack: Robotics, IoT & 5G

Connected devices, advanced robotics, and high-speed 5G deliver unmatched speed, accuracy, and responsiveness on the factory floor. - Cost Optimization Meets Sustainability

AI enables smarter resource use—helping industries reduce waste, lower costs, and meet sustainability mandates simultaneously. - Global Giants Drive the Innovation Curve

The US, Germany, Japan, and South Korea lead AI adoption; India, Brazil, and Southeast Asia are fast catching up.

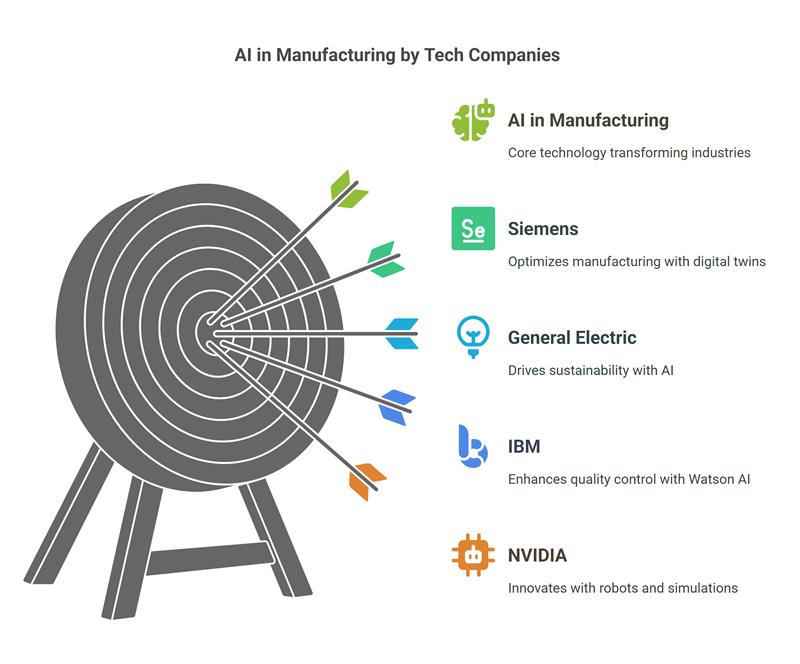

Global key players in the ecosystem:

Smart manufacturing thrives not on isolated breakthroughs, but through a powerful ecosystem where global tech giants collaboratively drive automation, intelligence, sustainability, and digital transformation forward.

Siemens uses digital twins and Industrial Copilot to optimize manufacturing, automation, and predictive maintenance.

General Electric uses AI, predictive analytics, and digital twins to drive smart sustainability in complex energy and manufacturing systems.

IBM focuses on Watson AI to enhance quality control, maintenance, and supply chain intelligence in manufacturing.

NVIDIA is driving innovation through Omniverse and Isaac, combining robots and simulations to create AI-powered manufacturing systems.

Samsung uses AI and computer vision in its factories to detect flaws in real time, improving product reliability and manufacturing efficiency.

Signicent has assisted numerous companies in transforming their novel ideas into impactful, market-ready solutions. By leveraging our strengths in technology scouting, patent landscape analysis, and in-depth market research, we’ve supported global manufacturers in navigating the evolving landscape of smart manufacturing.

From novel manufacturing ideas to sustainable materials, and from smart procurement strategies to predictive maintenance solutions, Signicent enables organizations to uncover white spaces, validate breakthrough technologies, and seize strategic opportunities.

Our work goes beyond insights — we bridge the critical gap between R&D and commercialization, helping firms accelerate product development, reduce operational costs, and future-proof their innovation pipelines.

If you are actively striving for such technological solutions and industry insights, then you can contact us. We offer a comprehensive analysis and provide services in White Space Analysis & Technology Gaps Analysis. We also help in research support via problem-solution approaches.

Each year Signicent provides consultancy to hundreds of organizations to help transform their innovations to value.

Future Outlook: Sustainable Automation in Manufacturing

AI is no longer a futuristic concept in manufacturing; it is a present-day reality and a critical enabler of competitiveness and resilience. Its ability to analyze vast datasets, identify complex patterns, predict future events, and automate intelligent actions is fundamentally reshaping how products are designed, made, and delivered.

While challenges related to implementation, skills, and change management exist, the overwhelming benefits – enhanced efficiency, superior quality, reduced costs, increased agility, and accelerated innovation – make AI adoption an imperative, not an option. AI in manufacturing signifies a pivotal move towards smarter, more autonomous, and data-centric production environments.

Companies that strategically embrace and integrate AI into their operations will not only optimize their current processes but will also unlock new capabilities and business models, positioning themselves as leaders in the next era of industrial evolution. The fusion of human ingenuity and artificial intelligence promises a future for manufacturing that is more productive, sustainable, and responsive than ever before.

About Signicent LLP

We assist businesses globally in their technology innovations, R&D, new product development, patents, valuation, product commercialization & market research needs.

Services Offered:

- Patent Landscape

- Patent Portfolio Analysis

- Patent Invalidity Search

- Patent Licensing Services

- Freedom to operate (FTO)

- Chemical Structure Search

- Design Patent Search

- Technology Scouting

- Technology Landscape Analysis

- Technology gap analysis

- Technology Intelligence

- Market Research

- Bio Sequence Search

- Manufacturers Search/ Supplier search

Elevate your Innovation and Research with Signicent’s cutting-edge approach to assist you with Technology and Market related matters alongside the IP aspect of the analysis.